ERW/HFW Pipe

Product:ERW (Electric Resistance Welded ) Steel Pipe, HFW Pipe, ERW Black Pipe

Application:Used for Oil/Gas/Water transmission,Machinery Manufacturing

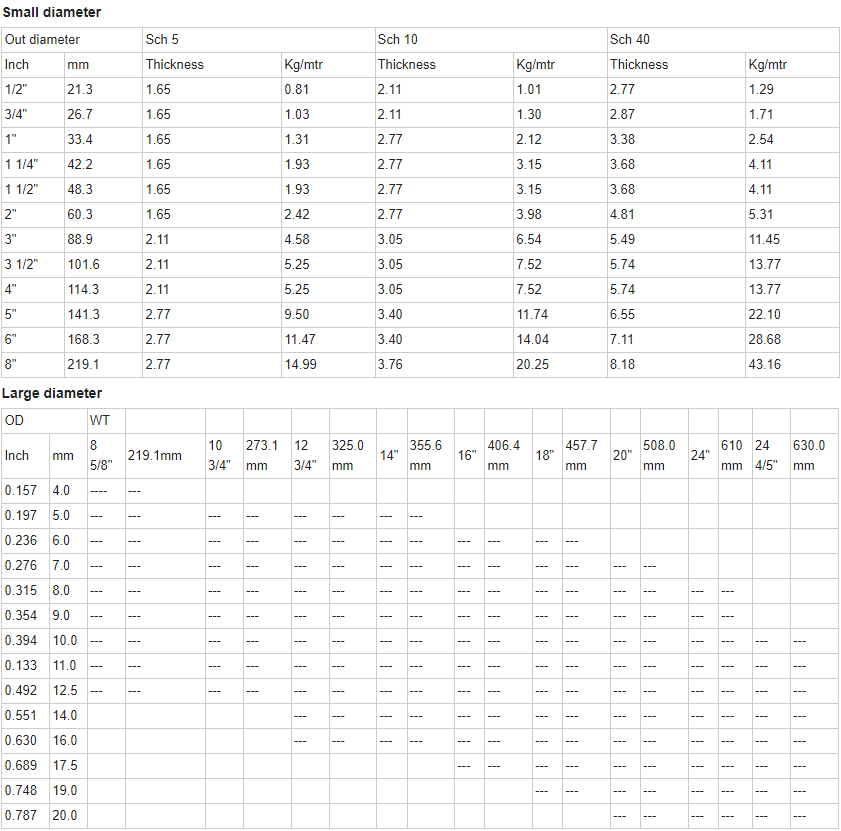

Size:OD: 21.3-660mm,WT: 1.0-20mm,LENGTH: 5.8/6/11.8/12m

Pipe Standard: API 5L PSL1/PSL2 Gr.A,Gr.B,X42,X46,X52,X56,X60,X65,X70

ASTM A53/A252/A500/A178/A135

EN10210/EN10219/EN10217/EN10208/EN10297

JIS G3441/G3444/G3445/G3452/G3454/G3456

BS1387/AS1163

The ERW steel pipe is also known as straight joint pipe. According to the wall density, the bonded tube is categorized into typical types and thick-walled types. We can offer items with personalized wall thickness according to customers’ particular requirement with a thickness deviation of no more than 0.25 mm.With sizes between 1/2 inch and 24 inch, our ERW steel pipes go through rigorous examinations and tests, so about make sure the welding quality, external size precision, ovality, cut lengths, pipe end quality, wall density tolerance, and packaging quality are all conforming to API5L, ASTMA53, GB/T9711.1, or GB/T3091 standards. Also, we can make the item according to the standard needed by customers.

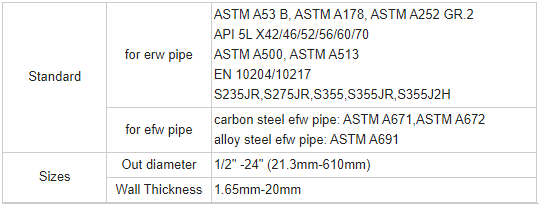

Standard:

ASTM 5L, ASTM A53, ASTM A178, ASTM A500/501, ASTM A691, ASTM A252, ASTM A672, EN 10217

Steel Grade:

API 5L: PSL1/PSL2 Gr.A, Gr.B, X42, X46, X52, X56, X60, X65, X70

ASTM A53: GR.A, GR.B,ASTM A500 JIS G3466

EN: S275, S275JR, S355JRH, S355J2H,EN10219-1 ,EN10217-1

GB: Q195, Q215, Q235, Q345, L175, L210, L245, L320, L360-L555

ASTM A53: Standard Specification for Pipe, Steel, Black and Hot-Dipped, Zinc-Coated, Welded and Seamless

API 5L: Specification for Line Pipe(Two levels PSL 1 and PSL 2 of seamless and welded steel pipes for use in pipeline transportation systems in the petroleum and natural gas industries.)

A252: Standard Specification for Welded and Seamless Steel Pipe Piles

A500: Specification for Cold-Formed Welded and Seamless Carbon Steel Structural Tubing in Rounds and Shapes

A135: Standard Specification for Electric-Resistance-Welded Steel Pipe

A178: Standard Specification for Electric-Resistance-Welded Carbon Steel and Carbon-Manganese Steel Boiler and Superheater Tubes

ASTM A249: Specification for Welded Austenitic Steel Boiler, Superheater, Heat-Exchanger, and Condenser tubes

ASTM A250: Specification for Electric-Resistance-Welded Ferritic Alloy-Steel Boiler and Superheater tubes

ASTM A688: Specification for Welded Austenitic Stainless Steel Feedwater Heater tubes

ASTM A778: Specification for Welded, Unanneled Austenitic Stainless Steel Tubular Products

ASTM A803: Specification for Welded Ferritic Stainless Steel Feedwater Heater tubes Structural ERW tubing

ASTM A501: Specification for Hot-Formed Welded and Seamless Carbon Steel Structural tubing

ASTM A847: Specification for Cold-Formed Welded and Seamless High Strength, Low Alloy Structural Tubing with Improved Atmospheric Corrosion Resistance

ASTM A618: Specification for Hot-Formed Welded and Seamless High-Strength Low-Alloy Structural tubing

ASTM A214: Specification for Electric-Resistance-Welded Carbon Steel Heat-Exchanger and Condenser tubes

ASTM A249: Specification for Welded Austenitic Steel Boiler, Superheater, Heat-Exchanger, and Condenser tubes

ASTM A498: Specification for Seamless and Welded Carbon, Ferritic, and Austenitic Alloy-Steel Heat-Exchanger tubes with Integral Fins

ASTM A851: Specification for High-Frequency Induction Welded, Unannealed, Austenitic Steel Condenser tubes

ASTM A554: Specification for Welded Stainless Steel Mechanical tubing

ASTM A513: Specification for Electric-Resistance-Welded Carbon and Alloy Steel Mechanical tubing

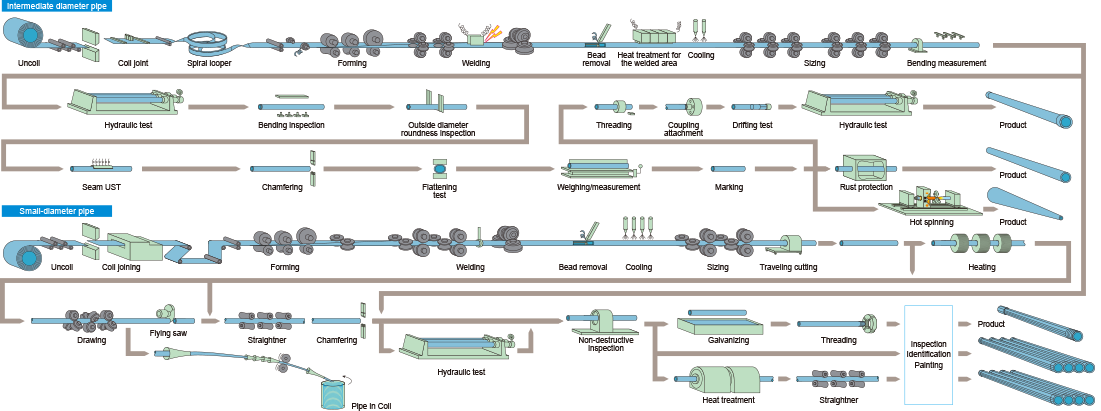

Manufacturing Process of ERW steel pipe:

Electric Resistance Welded (ERW) pipe is manufactured by cold forming a flat steel strip into a rounded tube and passing it through a series of forming rollers to obtain a longitudinal seam. The two edges are then simultaneously heated with a high frequency current and squeezed together to form a bond. The longitudinal ERW seam does not require filler metal.

Packing:

Packing: Plastic plugs in both ends, Hexagonal bundles of max. 2,000kg with several steel strips, Two tags on each bundle, Wrapped in waterproof paper, PVC sleeve, and sackcloth with several steel strips, Plastic caps.

Test: Chemical Component Analysis, Mechanical Properties (Ultimate tensile strength, Yield strength, Elongation), Technical Properties (Flattening Test, Bending Test, Hardness Test, Impact Test), Exterior Size Inspection, Hydrostatic Test, NDT TEST ( ET TEST, RT TEST, UT TEST)

- Country of origin

- China