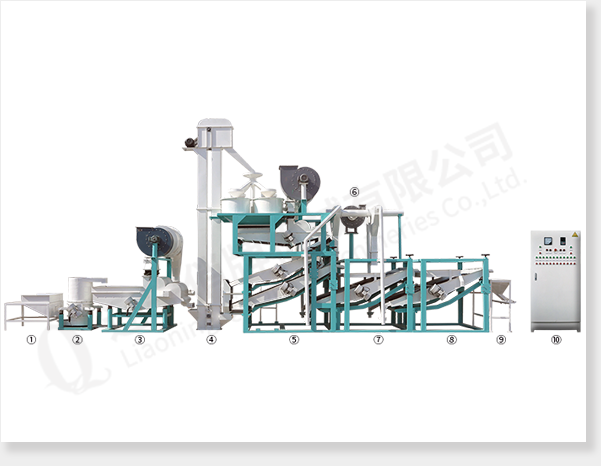

Sunflower Seed Cleaning Dehulling and Separating Equipment TFKH-1500

Component:

① input hopper ② spiral elevator ③ multi-functional cleaner ④ bucket elevator ⑤ main part of the equipment(dehullers,air separator and seed-kernel separator) ⑥pneumatic system of back-flowing materials ⑦ seed-kernel reseparator1 ⑧ seed-kernel reseparator2⑨ kernels bin ⑩ electric control cabinet

Functions and Features:

This equipment can complete the cleaning, dehulling, shells-removing and seed-kernel separating of sunflower seeds at one time, and it's the optimum choice for sunflower kernel processing industry in the world today. It features high dehulling rate, high percentage of whole kernels, high automation degree, easy operation and maintenance, etc.

Technical Parameters:

Model: Vertical Model

Power: 17.46kw (380v)

Input Capacity: 0.7-1.0mt/h

% of Whole Kernels (broken kernel is less than 1/2 of the whole one): 90%min.

% of Inshell in Kernels: 5%max.

Overall dimension (L * W * H): 11.6×3.3×5.5 m

Model: Horizontal Model

Power: 17.7kw(380v)

Input Capacity: 0.7-1.0mt/h

% of Whole Kernels (broken kernel is less than 1/2 of the whole one): 90%min.

% of Inshell in Kernels: 5%max.

Overall dimension (L * W * H): 14.75×2.9×4.4 m

Model: New Model

Power: 20.24kw(380v)

Input Capacity: 0.8-1.25mt/h

% of Whole Kernels (broken kernel is less than 1/2 of the whole one): 90%min.

% of Inshell in Kernels: 5%max.

Overall dimension (L * W * H): 13.1×2.92×5.4 m

- Model

- TFKH-1500

- Country of origin

- China