Rubber Tyred Gantry Crane

Rubber Tyred Gantry Crane:

• Capacity: 5~900 tons

• Span: 5~50m

• Lifting height: 5~30m

• Lifting Speed: 0-4m/Min

• Crane Speed: 0-60m/Min

• Operating Temperature: -20℃~40℃

• Customize

The Most Cost Effective Lifting Solutions:

The rubber tyred gantry crane offers high efficiency, flexibility, and mobility, which can be used in various industries and applications. Such as casting yards, bridge erection, external logistics, and storage, wind energy, power plants, steel mills, ports, etc. Huada Lift offers different types of industrial rubber tyred gantry crane for sale: single girder, double girder, and A-frame, which can meet any working conditions. Tell us your specific requirements and our professional engineer team will provide you a customized solution.

Single Beam Rubber Tyred Gantry Crane:

• Lifting capacity: 70 Ton

• Span: 14 m

• Lifting height: 7.5 m

• Customize

Double Beam Rubber Tyred Gantry Crane:

• Lifting capacity: 40 Ton + 40 Ton

• Span: 9.5 m

• Lifting height: 6.5 m

• Customize

A Frame Rubber Tyred Gantry Crane:

• Lifting capacity: 160 ton

• Span: 34 m

• Lifting height: 13.5 m

• Customize

Straddle Carrier Crane:

• Lifting capacity: 60 Ton + 60 Ton

• Span: 10 m

• Lifting height: 9.5 m

• Customize

Features:

Huade Lift focus on the manufacture & design of straddle carriers. We are committed to creating value for our customers and provide with the most economical and efficient material handling solutions.

• Customized design: capacity, span, lifting height, spreader.

• Great flexibility: eight steering modes options.

• Good linkage: two units can be linked to lift long objects.

• Flexible ground beam: designed to adapt to larger slope of the ground.

• Equipped with night lighting, realize 24-hour operation.

• Equipped with jacking cylinder, convenient for maintenance operations.

• Diesel power, oil-electric combination and pure electric power options.

• International famous brand parts, such as Cummins, Dike, Advance, etc.

• Remote control and driver's room control.

Applications:

Rubber tyred gantry cranes are widely used in various industrial applications. Here are some of the typical applications and industries where rubber tyred gantry cranes are employed:

• Concrete Precast: Rubber tyred gantry cranes are used to lift and transfer concrete beams and other precast elements in construction projects.

• External Logistics Storage: These cranes are utilized in outdoor storage areas, such as logistics yards, to handle and move containers, pallets, and other heavy materials.

• Steel Mills and Workshop: Rubber tire gantry cranes are also used in steel mills for the handling and movement of steel beams, coils, plates and other products. They are often equipped with special attachments, such as lifting magnets or clamps, for securely gripping and lifting steel products.

• Wind Energy: Rubber tyred gantry cranes play a crucial role in the installation and maintenance of wind turbines, including lifting and positioning turbine components.

• Road and Bridge Construction: Rubber tyred gantry cranes are employed to handle and position heavy components like girders and bridge sections during road and bridge construction.

• Ports and Shipyards: Rubber tyred gantry cranes are commonly found in ports and shipyards for container handling, loading and unloading cargo, and moving shipping containers.

Steering Modes of Rubber Tyre Gantry Crane:

The rubber-tyred gantry cranes are designed with a variety of steering modes to meet different working conditions of customers, including: longitudinal travelling, front steering, rear steering, crab steering, ackermann steering, pivot steering. Each steering mode offers unique advantages and is chosen based on the specific needs of the operation.

Highly Customized To Suit Your Needs:

Highly customized according to your needs, the special sling is used for lifting containers, modular houses, etc.

Functions:

• The main and the auxiliary trailer working synchronously well.

• Hydro-mechanical all-wheel mechanically controlled steering with loop design

• Optimized bolt-on coupling for easy coupling of chassis modules

• Multiple expansion options through additional equipment

• Ball bearing housing design module

• Travel Alarms and Strobe Lights

• Audible alarm

Options:

• Combination of longitudinal and transverse options

• Box-shaped center frame with high flexural strength

• Oscillating shaft with hydraulic shaft compensation system (horizontal adjustment)

• Automatic Variable Throttle

• Raised Cab

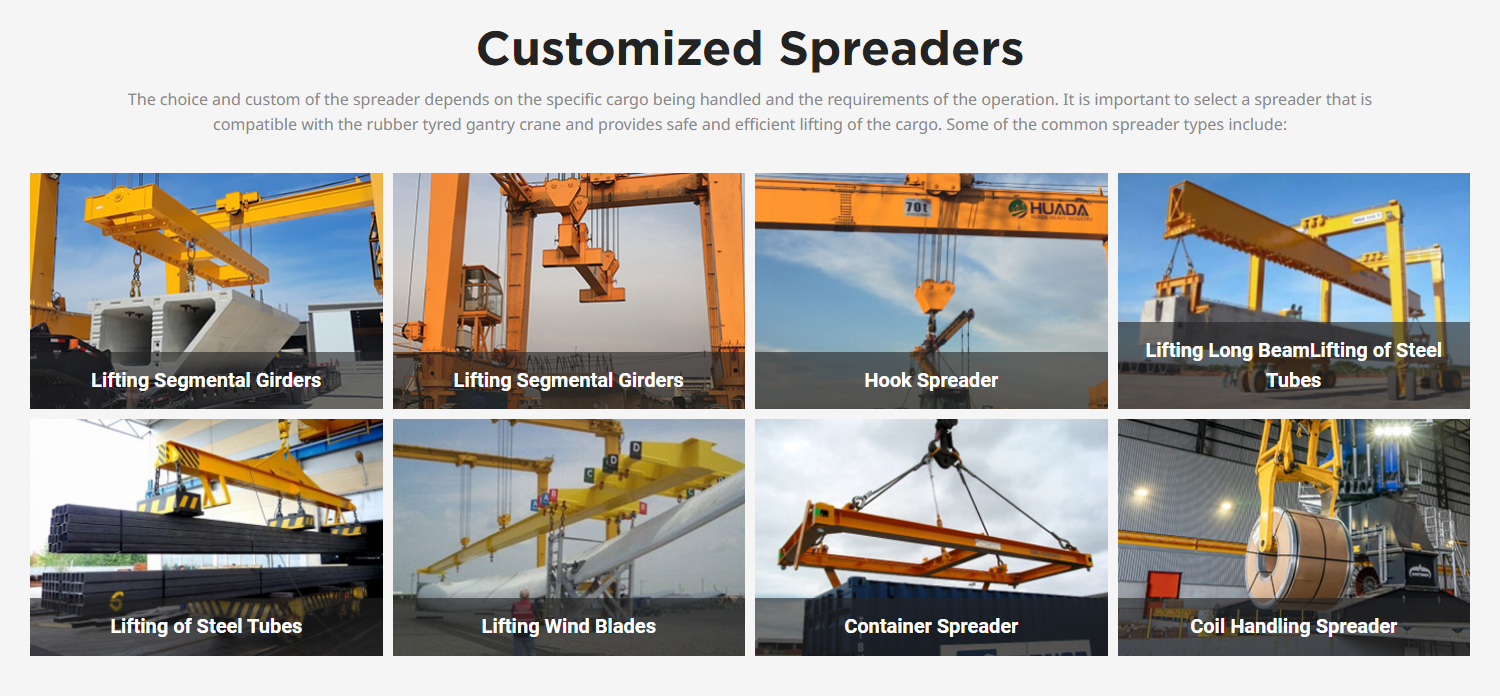

Customized Spreaders:

The choice and custom of the spreader depends on the specific cargo being handled and the requirements of the operation. It is important to select a spreader that is compatible with the rubber tyred gantry crane and provides safe and efficient lifting of the cargo. Some of the common spreader types include:

• Lifting Segmental Girders

• Lifting Segmental Girders

• Hook Spreader

• Lifting Long Beam Lifting of Steel Tubes

• Lifting of Steel Tubes

• Lifting Wind Blades

• Container Spreader

• Coil Handling Spreader

Frequently Asked Questions:

Huade lift Industry focus on Casting Yard and Bridge erection site one-stop product supply, which is from girder making, girder transportation, girder lifting to girder erection equipment etc.

Q. How long is the lead time for the rubber tire crane?

The delivery time of the rubber tire crane is generally 30 to 50 days. In addition, if special customization is required, the delivery time will be longer.

Q. Will the rubber tired gantry crane be tested before delivery?

In order to ensure the RTG crane performance & function and reduce the cost at the site, as a responsible rubber tire gantry crane supplier, we would do the pre-assembly & factory test before factory delivery, which minimize the site assembly work and facilitate the site assembly & test more quickly.

Q. Can you provide guidance for installation and commissioning?

There are two schemes for customers to choose from:

a: Free Remote on-line guidance: We have supported the site assembly & commissioning of straddle carriers by free on-line remote guidancethat save much time& cost for our customers.

b:Huade Lift will send engineers to customers site to guide site commissioning at client's cost.

Q. How long about the warranty period?

The warranty period of our products is 1 year. If there is a failure or component damage caused by quality problems within 1 year, our company is responsible for providing replacement parts free of charge.

- Country of origin

- China