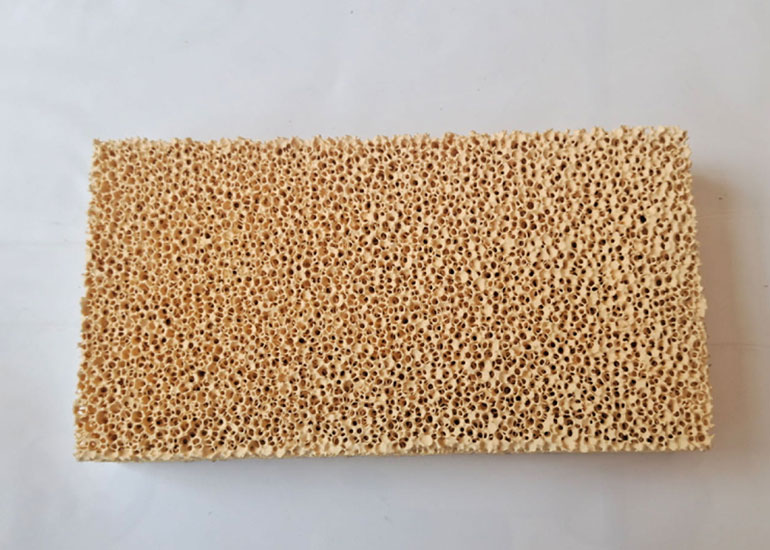

PLP series foam ceramic filters

PLP series foam ceramic filters are made of fine ceramic materials through special processes. They can be used for filtration and purification of cast steel, cast iron and non-ferrous alloys. They can significantly reduce blisters, slag holes, pores, inclusions and other defects, and improve surface quality. Improve machinability and mechanical properties, making it an ideal choice for producing high-quality castings. PLP series foam ceramic filters have the advantages of high porosity, high strength, good thermal shock resistance and thermal shock resistance, and can withstand large flow of molten iron filtration.

Operating guide:

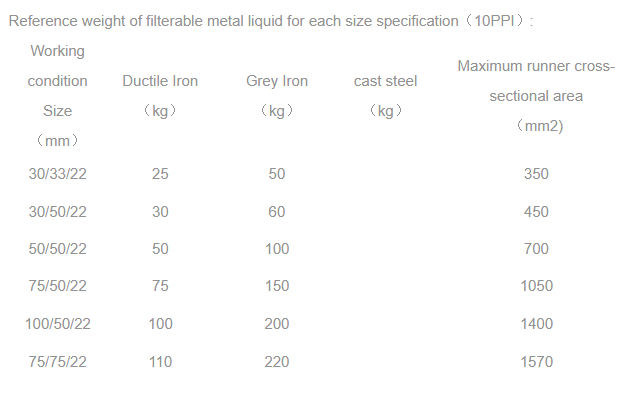

1. Dimensions and reference weight of filterable metal solution:

Dimensions:

Square: Products of various sizes from 30X30-150X150mm are available.

Round:φ40-150mm

PPI (number of holes/25mm): 6 10 15 etc.

2. PLP series foam ceramic filters can be placed in various parts of the casting system and should be selected according to the characteristics of the parts and production conditions. Generally speaking, the closer to the inner gate, the better the filtering and purification effect.

Precautions:

When loading, unloading, and transporting, care should be taken to prevent extrusion.

Packaging: carton packaging or packaging according to user requirements.

- Country of origin

- China