GM-HMC100 Horizontal Machining Center

According to the needs of users, it has equipped with special functional accessories such as borer head, vertical milling head, angle milling head and extended spindle, which greatly expands the use range of the machine tool. CNC HMC100 Horizontal machining center has the characteristics of high cost performance, wide range of speed regulation, reliable and stable operation, low noise and wide machining range (both rough machining and finishing machining).

Mechanical characteristics:

Full fairing and telescopic protection of the stainless steel shaft and optimal chip mobility.

High precision, high price spindle, large output power, high removal rate.

The structure design has high rigidity and high performance.

Internal structure and components:

Inverted T structure design, high rigidity, high performance production operation.

• CNC horizontal machining center

• Work table from 500x500mm to 1000x1000mm

• Table bearing capacity 750kg ~ 3000kg

• Spindle speed 4500rpm to 6000rpm

• Fast forward 36mm/min

• Spindle speed from 6500 RPM to 10000 RPM

Refer to Power Requirements:

Power correspondence: 55~90A, 220V, 60Hz, 3Φ, 25kW

Refer to Pressure Requirements:

Pressure source pressure: 5~7bar

Set pressure: 5bar

Ambient temperature: 0~45℃

Relative humidity: <90%RH

Air supply: 380l/min

- Brand

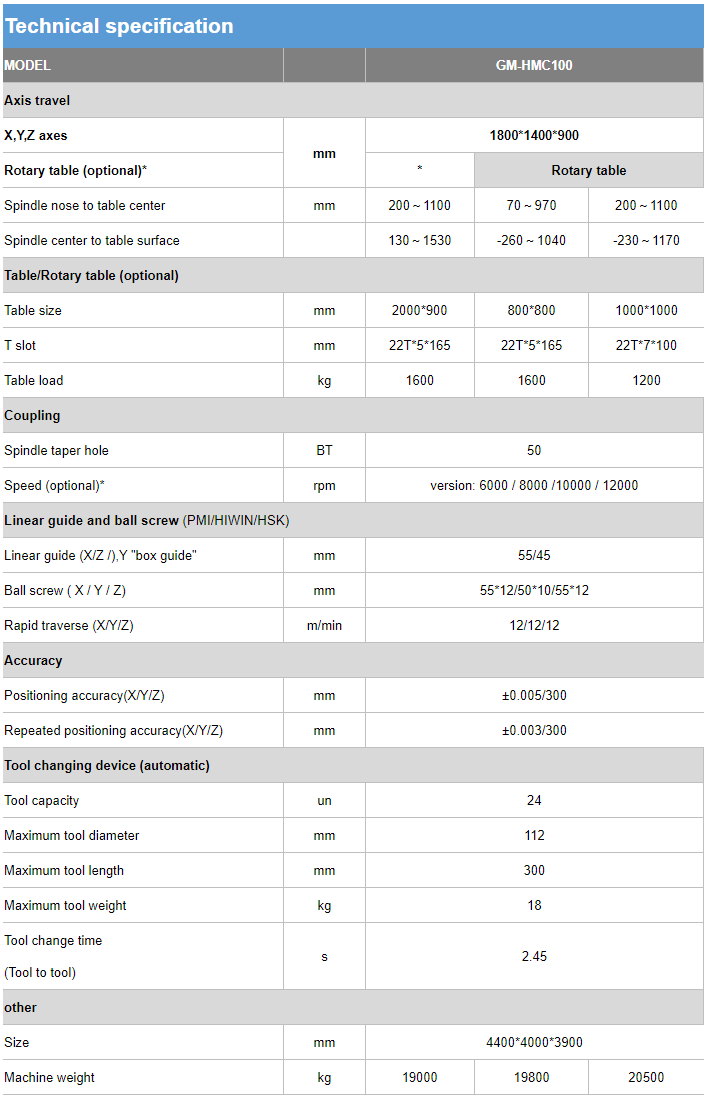

- GM-HMC100

- Model

- Glorymaq

- Country of origin

- China