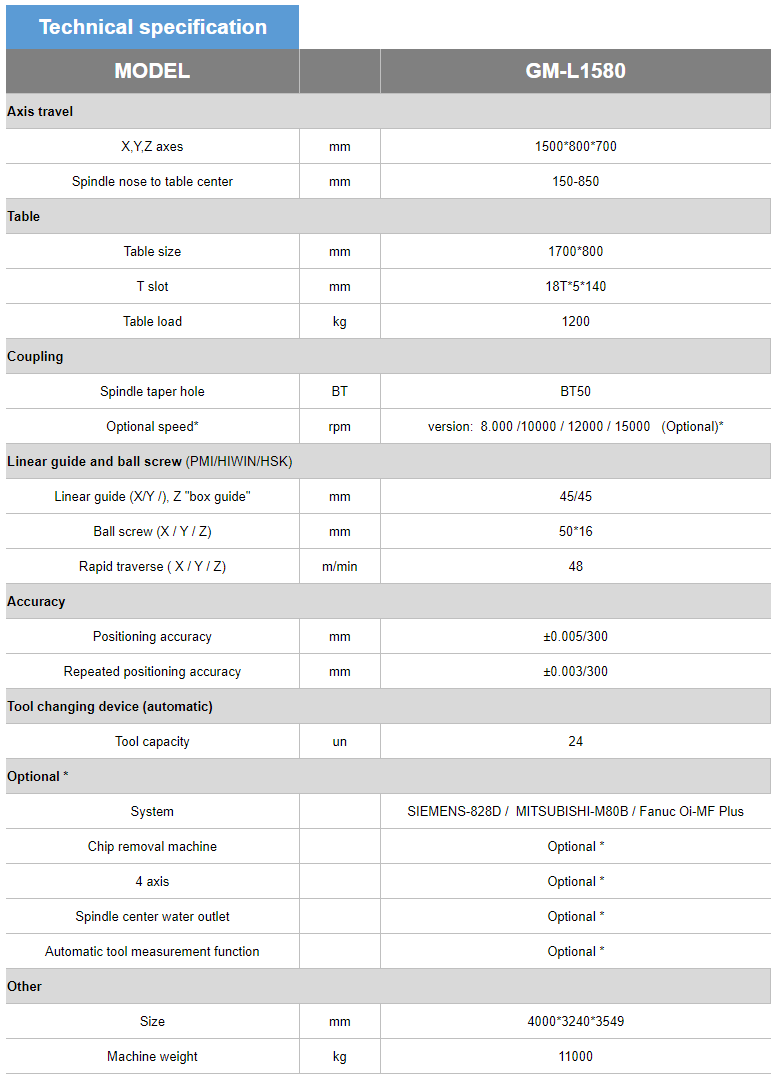

GM-L1580 Vertical Machining Center

VMC-L1580 Vertical Machining Center base adopts A-rib structure to improve the effect of vibration absorption, and the whole casting adopts box design with high bending stiffness.

The frame is made of high quality Mihanyue cast iron, which is tempered to eliminate internal stress and ensure optimum rigidity, accuracy and durability.

Years of experience data accumulation and rationalization of mechanism slenderness ratio design to improve the compressive strength and lateral bending strength of castings resulted in the high stiffness structure.

VMC-L1580 Vertical Machining Center High-speed tool changing mechanism design, using hunch should control, combined with efficient tool changing system, to achieve tool changing work, tool changing speed, to achieve high-speed tool changing function.

• Vertical machining center "box type" NC column

• Working table from 1700x800mm

• Table weight 1200kg

• Speed range from 8000rpm to 15000rpm(optional)

• Fast forward 48m/min

• Z-axis with hard rails provides higher vertical stability and better rigidity, resulting in higher machining accuracy and surface quality.

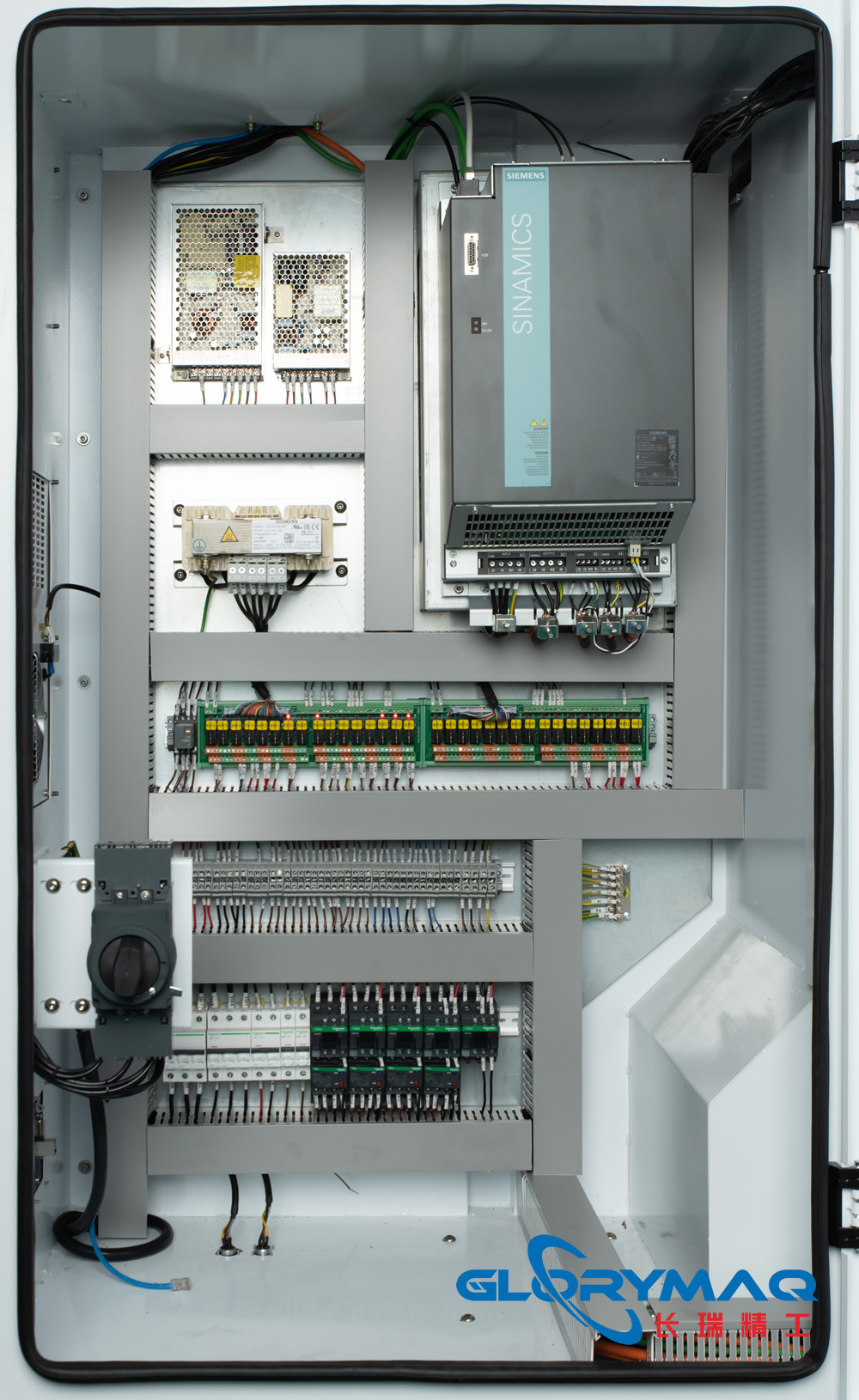

Refer to Power Requirements:

Power correspondence: 55~90A, 220V, 60Hz, 3Φ, 25kW

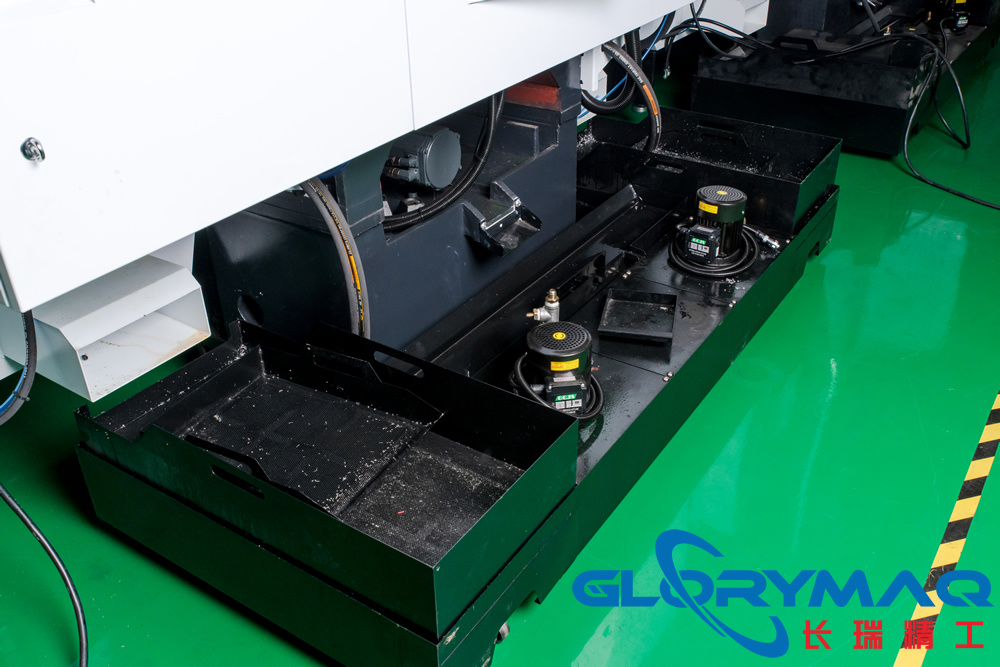

Refer to Pressure Requirements:

Pressure source pressure: 5~7bar

Set pressure: 5bar

Ambient temperature: 0~45℃

Relative humidity: <90%RH

Air supply: 380l/min

- Brand

- Glorymaq

- Model

- GM-L1580

- Country of origin

- China