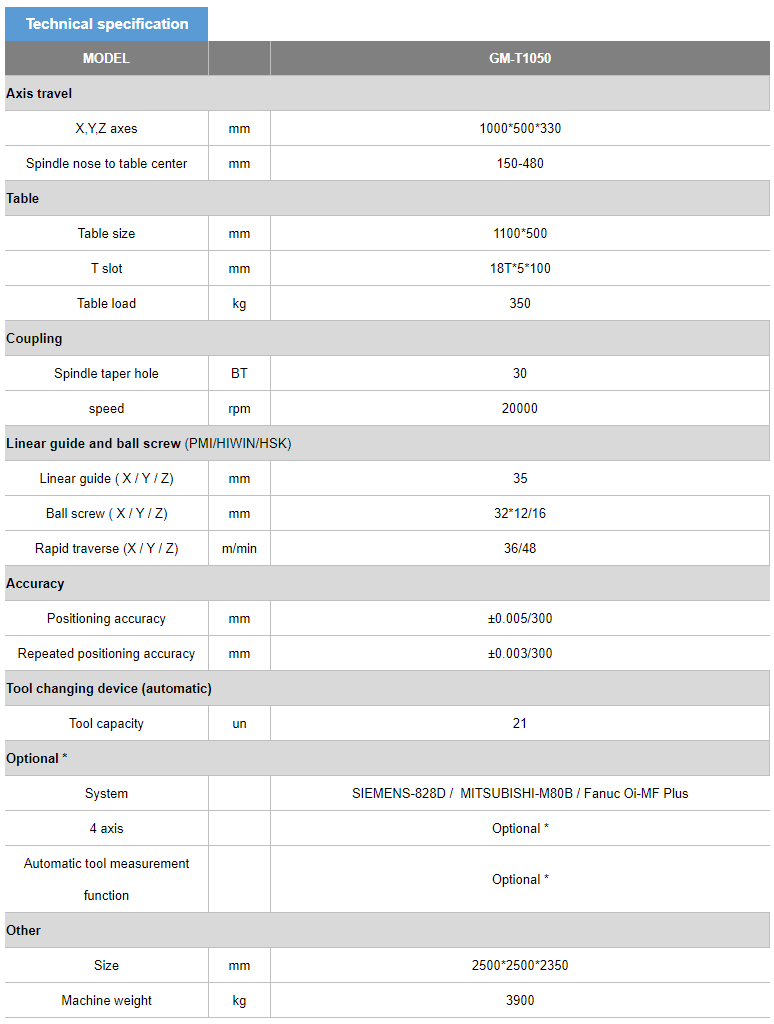

GM-T1050 Drilling and Tapping Machine

Mechanical characteristics:

CNC Drilling and tapping machine center base structure adopts six-point support design, which can improve rigidity and vibration resistance of the machine, and ensure good stability during the processing period.

The high-speed servo tool changer is fast and stable, which can reduce the tool changing time and non-processing time.

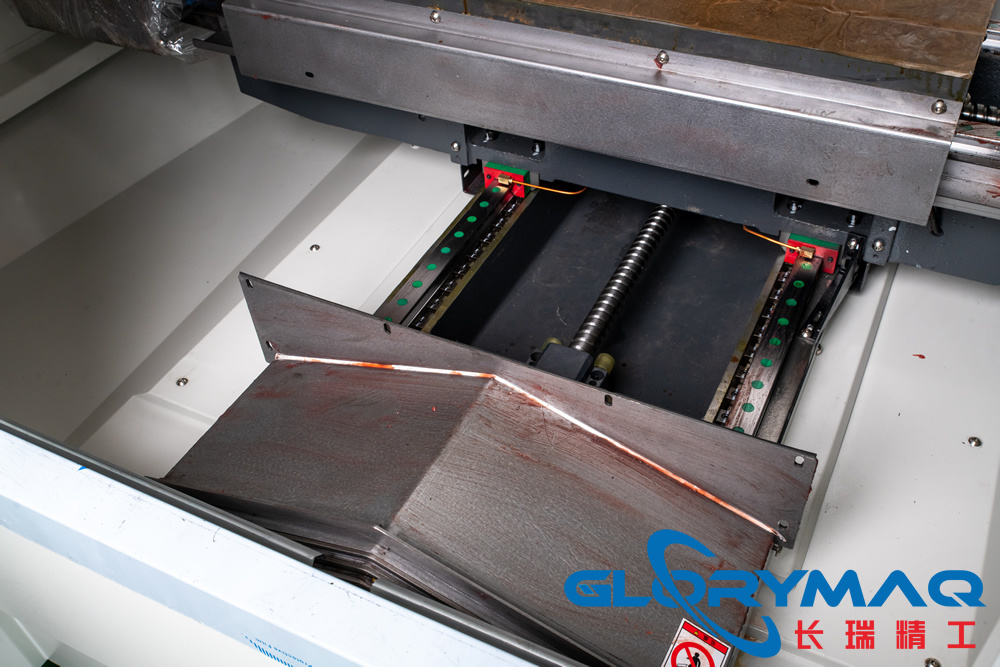

Fully enclosed shield design, backwashing with complete chip removal functions and high reliability.

High-speed and high-rigidity tapping.

Clamping arm tool library for quick and accurate tool replacement, suitable for small diameter drilling holes.

• High rigidity

• Design of high rigid bracing structure

• High efficiency

• Direct spindle transmission system

• Save space

• The machine takes up little space

After various heat treatment, the precision of the machine is effectivefor a long time, and the six points support to ensure high precision displacement performance.

The front knife library provides the speed of the tool replacement, which effectively improves the efficiency and reliability of production.

Fully enclosed protective cover design, backwash and chip removal function, high reliability.

Scope of application:

Precision parts, mobile phones, 3C products.

Refer to Power Requirements:

Power correspondence: 55~90A, 220V, 60Hz, 3Φ, 25kW

Refer to Pressure Requirements:

Pressure source pressure: 5~7bar

Set pressure: 5bar

Ambient temperature: 0~45℃

Relative humidity: <90%RH

Air supply: 380l/min

- Brand

- Glorymaq

- Model

- GM-T1050

- Country of origin

- China