Nickel Mesh

Nickel mesh, a high-quality woven metal product, offers excellent corrosion resistance, high-temperature performance, and strength. Widely used in various industries, it effectively filters, separates, and purifies solids and impurities. In hydrogen applications, it plays a crucial role in fuel cells, purification, and storage, driving sustainable energy development.

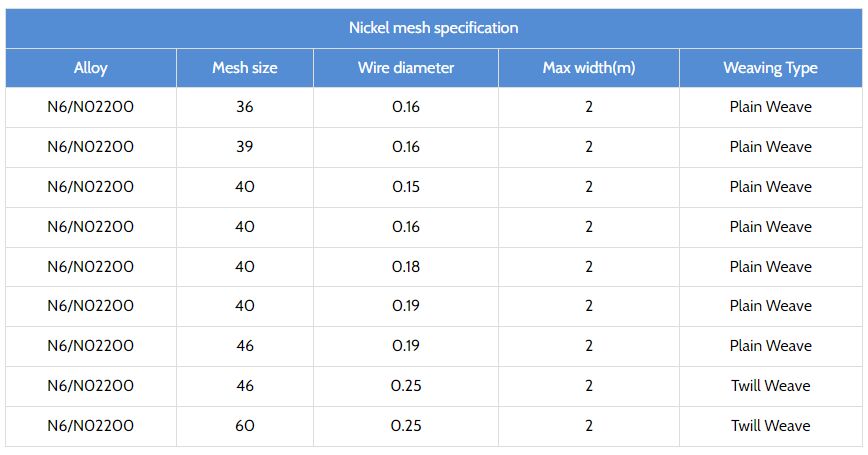

My company perennial spot supply: 10, 20, 30, 40, 50, 60, 80, 100, 120, 150, 180, 200, 250, 300, 350, 400 nickel wire woven wire mesh.

Nickel mesh is made of high quality nickel alloy wire woven metal mesh products, with excellent corrosion resistance, hightemperature performance, and mechanical strength. It is widely used in various industries, including chemical, petroleum, medicine, food processing, aerospace, and other fields. Nickel mesh can be used in filtration, separation, purification, and isolation operations to effectively capture and remove solid particles, impurities, and contaminants. In the field of hydrogen, nickel net plays an important role, used for fuel cell electrolyte layer support materials, hydrogen purification, hydrogen storage material, and anode material in the process of hydrogen production by water electrolysis. The excellent performance and reliability of nickel mesh make it the first choice for many processes and applications, which promote the development of sustainable energy.

Weaving method:

In plain weave, nickel alloy wires are interwoven according to certain spacing, forming a uniform and stable network structure. This kind of weaving makes the nickel mesh have good strength and stability, and can provide reliable filtration and separation effect. The choice of braid density and wire diameter can be adjusted according to the requirements of specific applications to meet the needs of different areas.

In twill weaving, nickel-alloy wires are interwoven at an Angle, usually 45 degrees, to form an oblique network. Compared with plain weave, oblique weave nickel mesh has higher strength and stability, and can withstand greater tension and pressure. This weaving makes nickel mesh more suitable for applications requiring higher strength and durability, such as filtering heavy loads or high-pressure fluids. At the same time, the diagonal nickel mesh can also provide greater porosity for better air permeability and liquidity.

Advantages:

• Excellent corrosion resistance: nickel mesh has excellent corrosion resistance, can resist the erosion of a variety of chemical substances, suitable for a variety of corrosive environment.

• High temperature stability: nickel mesh shows good stability under high temperature conditions, with heat resistance and oxidation resistance, can maintain long-term performance stability.

• Strength and durability: Nickel mesh is made of high-quality nickel alloy wire, which has excellent strength and durability and can withstand high pressure and mechanical stress.

• Filtration efficiency: Nickel mesh provides a variety of braided density and filtration accuracy options, can efficiently capture and separate solid particles, impurities and pollutants, to ensure fluid purity.

• Multi-field application: Nickel network in chemical, petroleum, medicine, food processing, energy, automotive, aerospace and other fields are widely used to meet the needs of different industries.

• Light and flexible: Nickel net is light weight and soft, easy to bend and shape, adapt to a variety of complex application scenarios.

• Strong machinability: nickel mesh has good plasticity and machinability, can be cold processing, hot processing and welding processing, to meet specific needs.

• Reliability and stability: The excellent properties and reliability of nickel mesh make it the preferred material for many critical applications.

These advantages make nickel mesh become an important material in many industries, widely used in different processes and technologies, and promote the development and progress of related fields.

Application:

• Chemical industry: Used for filtration, separation, and screening of chemicals to remove solid particles and impurities, ensuring product purity and quality.

• Petroleum and natural gas industry: Used as filters and separators in the processes of exploration, storage, and transportation of petroleum and natural gas, removing suspended particles, impurities, and sediments.

• Pharmaceutical and food processing industry: Used for filtration and purification operations in pharmaceutical and food processing, removing particles and impurities to ensure product safety and purity.

• Energy industry: In the field of energy, nickel mesh is used as a support material for the electrolyte layer in fuel cells, providing a supportive structure for electrical conductivity and gas transmission.

• Automotive industry: Applied in automotive exhaust systems as catalyst support materials, fuel filters, air filters, etc.

• Aerospace industry: Used as filters, isolation layers, and protective layers in spacecraft and aircraft, exhibiting high-temperature resistance and strength.

• Hydrogen energy field: Used as support materials for the electrolyte layer in fuel cells, hydrogen purification, hydrogen storage materials, and anode materials in the process of water electrolysis for hydrogen production.

- Country of origin

- China