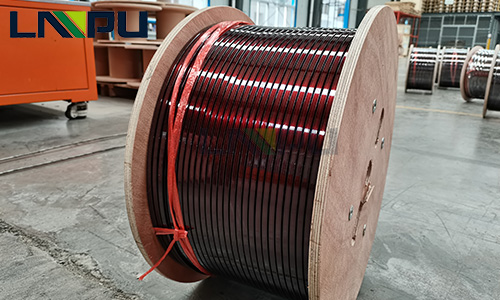

0.45-6mm Enameled Square Aluminum Wire

Advantages:

1. Compared with the copper enameled wire, Enameled Aluminum Winding Wires are easier to be winded. There is a solid oxide film on the surface of enameled aluminum wire which make it has a good insulating effect with a long life.

2. Due to the good insulating effect of aluminum film layer, it’s heat-resistant temperature can be 20 degrees higher than copper wire.

3. The greatest benefit of using aluminum is that it is 1/3 lighter than copper which significantly lower the production costs. It also attach to the solids easily and reduce the freight and operation during transportation.

4.The unit price of enameled aluminum wires are much lower than enameled copper wires.

Application:

1. Microwave transformers

2.Winding coils with light weight, high conductivity and good hea t resistance which used for high frequency signal transmission

3. Magnetic wire used in high frequency transformer, common transformer, inductance coils, electromotors, household electro-motors and micro-motors

4. Enamelled wire used in small-motor rotor winding .etc.

5. Magnet wires used in monitor deflection coil and degaussing coil

6. Other special magnet wire.

Types:

Polyester Enameled aluminum round wire(PEW);

Polyesterimide enameled aluminum round wires(EIW);

Polyesterimide over-coated with polyamide-imide enameled aluminum round wires(EIW/AIW);

Specifications:

Name: Enameled Square Aluminum Wire

Conductor: Aluminum

Standard: IEC, NEMA, GB, JIS

Thermal Class: 180(Class H), 200(Class C), 220(Class C+), 240(Class HC)

Insulation thickness: single or heavy

Packing: 30kg - 150kg ply-wood spool

- Country of origin

- China