Tensile Tester TF001

Tensile Tester TF001, also known as Tensile Strength Tester TF001, universal testing machine (UTM), universal tensile testing machine, etc.

The Tensile Tester TF001 is used to test the performance of various materials under tensile, peel, compression, bending, shear, tear, etc.

It is suitable for textiles, rubber, laminated films, packaging materials, pipes, woven tapes, leather, shoe materials, composite materials, paper, etc. With different fixtures, the tensile tester can be used to test different materials and kinds of tests.

TESTEX is a well-known tensile testing machine manufacturer in the industry and currently sells its products to more than 60 countries and regions worldwide.

The Features of Tensile Tester TF001:

1. High testing accuracy, force accuracy ≤ 1%, high test repeatability

The screw is high precision ball screw without backlash, which can do high-precision tests,

and the surface quenching hardness of the screw is high, so the service life can reach decades.

2. Designed for 6 different mechanical tests

tensile, compression, bending, tearing, shearing, and peeling tests.

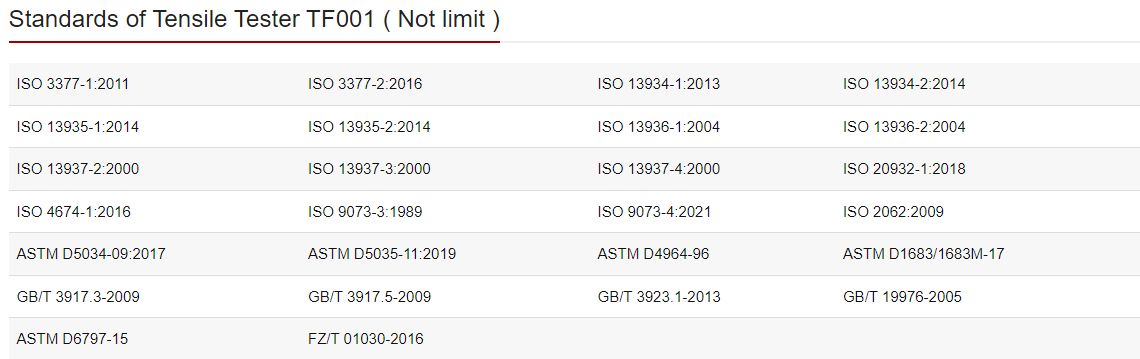

3. Applicable for 26 international standards

ISO3377, ISO 13935, ISO 13937, ISO 20932, ISO 4674, ASTM 5034, ASTM D4964-96 GB/T 3917.5-2009, FZ/T 01030-2016, etc.

4. We use 16 test parameters, for a more comprehensive test presentation

Displacement, maximum force, elongation, stress, maximum stress, bending stress, speed, force width, thickness, etc.

5. Stable testing process

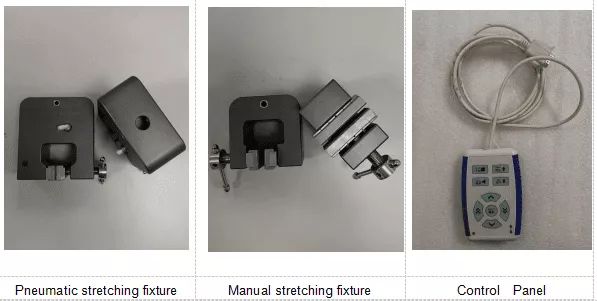

Equipped with a switchable pneumatic tensile fixture, there will be continuous sample tightening force

to reduce sample slippage when conducting the test.

6. Multiple safety settings

We have a built-in intelligent main power supply, a displacement alarm system,

an overload and emergency stop system and up and down stroke limiting sensors, which keep your equipment safe and stable.

The Specification of Tensile Tester TF001:

Test capacity: 250kg, 500kg

Test level: class 1

Max travel: 800 mm (without fixture)

Travel accuracy: ≤1%

Traverse speed: 1mm/min ~ 500mm/min

Speed accuracy: ≤1%

Test force range: 0.2%~100%FS

Force accuracy: ≤1%

Power:220 V 50Hz 3A 400W 110 V 60Hz 5A 400W

Weight: Net weight: 85kg Packed weight: 140kg

Dimensions: Machine: 680x500x1450 mm Packed: 780x600x1590 mm

Standard fixture and corresponding standards:

Manual stretching fixture should be equipped with: 25×25, 25×50, 25×75 clips

ISO 9073-3 ISO 13934-1 ISO 13934-2

ISO 13935-1 ISO 13935-2 ASTM D5034

ASTM D5035

Optional fixture and standards:

The Pneumatic tensioning fixture & footswitch are equipped with:25×25,25×50,25×75 clips

Optional fixture and corresponding standards:

U-shaped Fixture ASTM D4964

Yarn Fixture I SO2062

Bursting Fixture ASTM D6797 FZ/T 01030 GB/T 19976

Leather Tearing Fixture ISO 3377-2

Standards of the optional manual tension fixture:

ISO 9073-4 ( require 25x100mm clips) ISO 3377-1

ISO 13936-1 ISO 13936-2

ISO 13937-2 ISO 13937-3 ISO 13937-4

ISO 20932-1 (need to match the linear fixture which needs to be changed by your choice about the type of fixtures)

ISO 4674-1 GB/T 3917.3 GB/T 3917.5 GB/T 3923.1

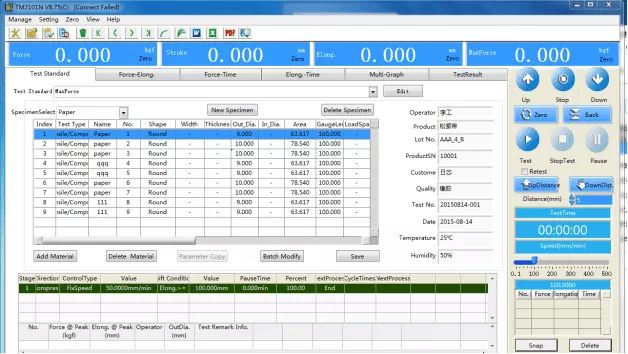

Computer Configuration of Tensile Tester (Optional):

• CPU for the Intel Celeron (Celeron) 2GHz or more CPU

• Memory at least 512MB, recommended more than 1GB

• Hard disk space above 2GB

• Display resolution of 1024 × 768 or more.

• Printer compatible with the operating system (if output reports are required)

• The applicable operating system for Microsoft’s Windows XP, Windows 7, Windows 8, Windows 10

• If you need to output the report in Word format, you must install Microsoft’s Microsoft Word 2003, 2007, and 2010 versions of the software.

Why Choose TESTEX Tensile Tester TF001

Strictly meet standards:

All data for the tensile tester meet the standard parameters.

Consistency with international third-party laboratories:

The test data are comparable to the test results obtained by well-known international third-party laboratories.

High repeatability:

With the same set of samples, and the same machine, and after multiple tests, the results are consistent.

High reproducibility:

Whether with the same set of samples, or different machines of the same model, after multiple tests, the results are consistent.

Longer service life:

For all the tensile testers manufactured by TESTEX, before mass production, prototypes are made and required to pass the strict Reliability Test, i.e. tested under challenging environments such as high and low temperature, high speed and high load, etc., to ensure the expected serving life no less than 10 years.

User-friendly transparent warranty policy:

Textile testing machines, 14 months free warranty (12 months normal warranty time + 2 months shipping time). And all spare parts, 3 months free warranty.

We provide full life-cycle support for the tensile testing machines, so feel free to contact our service team with any questions you may have.

Recommended Tensile Testers —How to choose a tensile tester?

1. The universal tensile testing machine should be selected according to the standard adopted and the region where it is sold.

Because different regions adopt different standards. Usually, European customers widely accept the ISO standard system, American customers widely recognize the AATCC and ASTM standard system, while Japanese customers are more inclined to the JIS standard system. Generally, tensile tester manufacturers will indicate in the product manual which standards apply, certainly, you can consult the manufacturer.

2. Consider the tension range of the test material (maximum tensile strength).

The difference in the tension range of the test material will determine the size of the sensor, and the structure of the tensile strength testing machine, but of course, this has little effect on the price (except for the double column type). For general textile testing, a maximum tension of 200N is sufficient. Therefore, the purchase of a single-column tension machine can be. TESTEX universal tensile machine maximum tension of 2500N, a broader range of applications; if the maximum tension needs to exceed 5000N should choose a double-column type.

3. According to the test needs to choose the appropriate maximum stroke.

Usually, the maximum stroke is the distance between the upper and lower fixture (test stroke) + the height of the upper fixture + the height of the lower fixture + the height of the sensor. Because different test materials will choose different fixtures, so choose a good fixture to know the specific test stroke. In general textile testing, the stroke in 600-800mm can be. Material elongation of more than 1000% can be selected stroke 1000 or 1200mm.

Test Method:

The definition:

A tensile tester, also named a universal material testing machine, is a kind of tester used for adding the mechanical force to fabrics under the test of their mechanical properties such as instrumentation static load, tensile, compression, bending, shear, tear and peel. It is also suitable for testing various physical and mechanical properties of plastic plates, tubes, profiles, plastic film and rubber, wire and cable, steel, glass fiber, and other materials, becoming an indispensable testing machine for boosting material development, teaching research, quality control, and other aspects. The fixture is a crucial componence of the tester. And different materials call for different fixtures, which plays an important role in finishing the test smoothly and the accuracy of the test result.

Test Object:

The tensile tester is mainly applicable to determine the tensile strength of metal and non-metal materials subject to compression, bending, shear, peeling, tearing, etc, such as rubber, plastic, wire and cable, safety belt, insurance belt, plastic profiles, waterproof coil, copper and so forth.

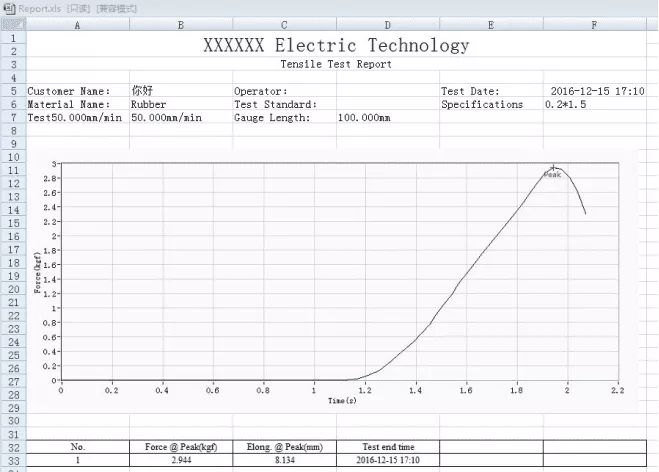

Primary Features:

Measure the displacement by the imported photoelectric encoder. The controller adopts an embedded single-chip microcomputer structure. There is powerful measurement and control software inside the machine which integrates the function of measurement, control, calculation, and storage into one system. It can also carry out the automatic calculation of stress, elongation (need to be equipped with an extensometer), tensile strength and elastic modulus, and even statistics of results. Moreover, it has the function of recording the maximum force, fracture point, force, and elongation at the specified point. It is also characterized by the dynamic display of the test process and test curve by the computer which is used for the data processing. Once the test is completed without any error, you can re-analyze and re-edit the data by enlarging the curve in accordance with the graphic processing module. Finally, you can print the report which will denote that the performance of the product has met the international advanced level.

Application Industry:

The tensile tester is extensively used across a wide range of industries, such as measurement and quality inspection, rubber and plastic, metallurgy and steel, machinery manufacturing, electronic appliances, automobile production, textile and chemical fiber, and commercial arbitration, and technical supervision departments, petrochemical and so on.

Notes:

一 When adding load on the tensile testing machine, the pointer chattering keeps or stops operation from time to time. There are three reasons for this situation.

There is wear in the clutch gear which needs to repair or replace.

There is wear in the leather washer of the friction disk or spring, which needs to replace with another leather washer or spring.

The displacement of the manipulation handle needs to adjust the manipulation handle to match well with the tooth groove.

二 When tensile testing machine pendulum comes back to the original position too fast or slow. There are also three reasons for this situation.

1 the buffer valve block is not properly placed: adjust the buffer valve to the appropriate position.

2 hydraulic oil viscosity is too low or too high: should replace the hydraulic oil with the appropriate viscosity.

3 there is smudginess in the buffer valve, oil pipe, or hydraulic oil: clean the buffer valve and oil pipe. should replace the hydraulic oil.

Machine Maintenance:

1 Regularly check the screws in the jaw area. If they become loose, you should tighten them in time.

2 The sliding surface of the steel plate contacting with the liner and the dovetail groove surface on the liner should be kept clean and regularly coated with a thin layer of MoS2 (molybdenum disulfide) grease.

3 Regularly check the transmission of the sprocket. If they become loose, please re-tension the tension pulley.

4 If there is no need to use the machine for a long time, please close the controller and computer.

5 According to the use of the machine and the service life of the oil, regularly replace the oil suction filter and filter element, the hydraulic oil, and regularly check whether there are oil leaks at the host and oil source. If there is any oil leak found, the sealing ring or combination gasket should be replaced in time.

Testing principle:

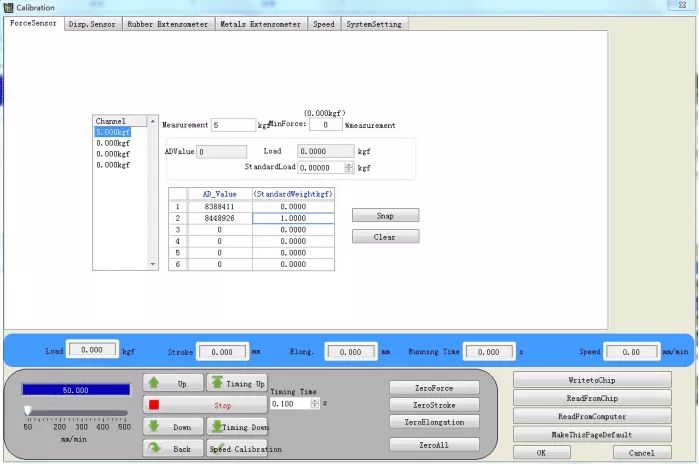

One end of the sample to be tested is held by the upper gripper, and the other end is applied with the standard prescribed pre-tension. It is clamped by the lower gripper. The lower gripper stretches the sample at a constant rate during the test, and the lower gripper drops at a displacement that is the elongation of the sample. The tensile force on the sample is converted into an electrical signal by the sensor connected with the upper gripper, which is amplified by the amplifier and converted by the A/D converter, and the force on the sample during the stretching process is calculated by the microcontroller, and the corresponding data chart is output for reference.

Test procedures (taking the textile tensile test as an example):

1. Preparation of specimens. According to the fabric species, choose the shape of the test strip, cut the specimen according to the specified specimen size, and the length direction should be parallel to the warp (longitudinal row) or transverse (or horizontal column) of the fabric. Each sample of warp and weft direction specimens at least 5 pieces, and in the standard atmospheric conditions to adjust the wet 4h.

2. Prepare a tensile testing machine. According to the shape of the fabric with the appropriate clamping fixture.

3. According to the requirements, adjust the upper and lower clamp spacing (clamping length), and stretching speed.

4. Clamp the specimen. First, clamp one end of the specimen in the center of the upper clamp, and then put the other end of the specimen into the center of the lower clamp and straighten it under pre-tension; then tighten the lower clamp (or use the loose clamping method).

5. Start the button to begin repeated testing and output the data information chart.

FAQs:

1. How does the loading rate affect tensile properties?

The rate at which a test is performed can have a significant effect on tensile properties. Materials such as plastics, polymers, steels exhibit tensile properties that are very sensitive to testing rates. Consequently, these types of materials have higher tensile strengths and lower elongation values at faster speeds.

Standardized test methods developed for these materials often specify a loading rate or a range within certain limits. In order to obtain accurate and repeatable results, it is critical to maintain the same loading rate when testing these materials.

We recommend keeping up with the recommended calibration schedules to ensure load and strain measuring devices provide accurate and repeatable results.

2. How does specimen alignment affect tensile properties?

When a specimen is properly aligned, the top and bottom test fixtures are in one straight line with the direction of force, the loading train, and with one another. In addition, the specimen is clamped between the top and bottom grip jaws at the same center line.

- Model

- TF001

- Country of origin

- China