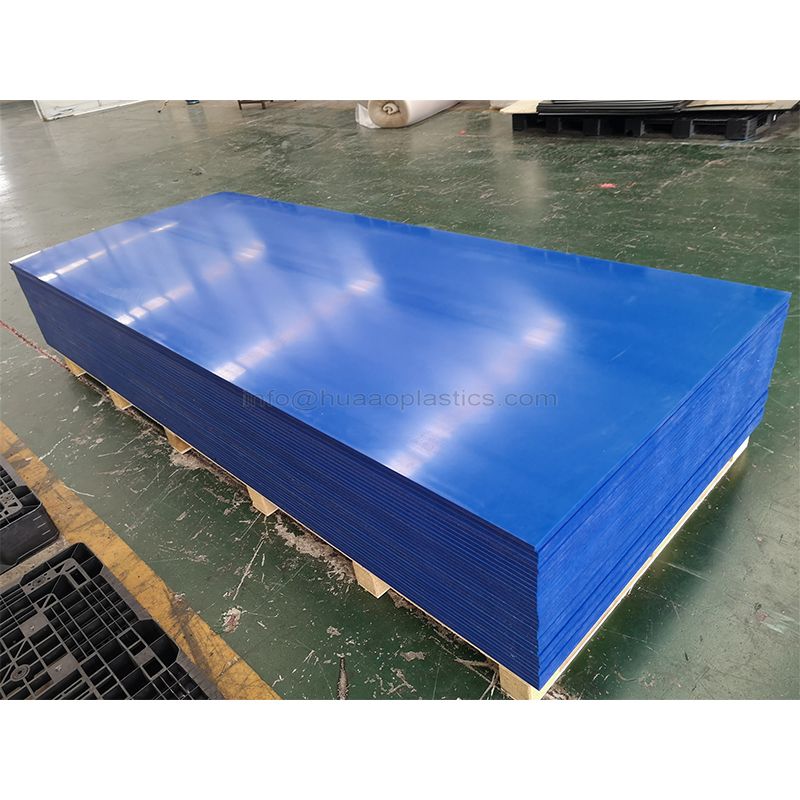

UHMWPE Sheet

Ultra High Molecular Weight Polyethylene (UHMWPE) is a thermoplastic engineering plastic that combines the superior properties of all plastics. Mechanical properties are higher than high-density polyethylene, with outstanding wear resistance, impact resistance, low temperature wear resistance, stress crack resistance, high temperature creep resistance, low friction coefficient, self-lubricating, excellent chemical resistance Excellent performance such as fatigue resistance, noise damping, and nuclear radiation resistance. Can replace carbon steel, stainless steel, bronze and other materials used in textile, paper, food machinery, transportation, medical, coal, chemical and other sectors.

UHMWPE sheets are used for conveyor guide rails, belt scrapers, chain guides, bearings, sprockets, rollers and wear plates. UHMWPE areas of applications also include chemical tanks, mining processing equipment, bulk material handling, transportation and recreation equipment.

Advantages of UHMWPE Sheets:

• Highest abrasion resistance of any polymer, 6 times more wear resistant than steel

• Anti-Weather & Anti-Aging

• Self-lubricating, Very low coefficient of friction

• Excellent chemical & corrosion resistant

• superior impact resistant, Noise- absorption, Vibration-absorption

• Temperature range: -2600C ~ +800C; Very high resistance to cold,doesn't become fragile even under -1800C

• High tensile Strength

• Non-Toxic and smell

• UV resistance

• Flame Retardant; Relatively low in water absorption

• Excellent electrical properties

• Good performance in resisting environment stress crack, 200 times of ordinary PE

• No adhesion

• Light weight and easier to handle and fix

• Cost efficient; Resulting in low energy consumption

• Does not rot, split or crack; 100% recyclable

• Great liner material for industrial material handling applications--Easy Reprocessed

UHMW-PE Sheet Applications:

• Paper industry, food, packaging, paper, environmental protection, textile

• High wear-resistant plate Transportation industry, silo lining, port machinery, mining machinery, construction machinery, chute, hopper lining

• Anti-static board Anti-static parts such as mines, docks, grain processing, etc.

• Flame retardant board for underground operations in mines, mainly used for flammable parts of coal bunker

• Anti-ultraviolet board Temporary construction pavement, open-air silo, funnel and other outdoor parts

• Radiation protection panels Nuclear power plants, hospital radiation protection products, etc.

• Skid plate Crane, construction, etc.

• Self-lubricating plate Coal bunker, dump truck, etc.

• Fender plates Ports, docks, etc.

• Microplate, filter plate, sewage treatment, etc.

• Modified ultra-high board Construction and pharmaceutical equipment, belt conveyors, etc.

• Double color plate Spiral machine lining

• Glass bead plate Pharmaceutical equipment

• Hanging rubber plate Port, wharf, buffer strip, baffle, filter plate

What is the performance of UHMWPE sheet?

UHMWPE sheets have incredible abrasion resistance. It is more abrasion resistant than almost any engineering plastic and may be one of the best materials for lining chutes and hoppers for products such as sand, aggregate and concrete or any other highly abrasive moving product.

Another important property is the very low coefficient of friction of UHMWPE sheets. It is the lowest of all engineering plastics and can produce parts with very long life and very low resistance, which means very few people will stick to it. It is also resistant to many dilute acids, solvents and cleaning agents.

The maximum continuous operating temperature of UHMWPE is +90°C and the short-term operating temperature is +120°C. It is a very tough material with the highest impact strength of any thermoplastic manufactured today.

HuaAo offers a superb selection of UHMWPE sheets for sale with excellent sliding properties, more details please contact us.

- Country of origin

- China