WGS-C200 Slab/Strip Width Measuring System

The width measuring system adopts dual industrial CCD cameras to proceed the online measurement of the steel plate on the roller bed by using the principle of stereo vision technology, and combines the high-speed digital signal processing technology and programming software to process the signals accordingly, and displays the relevant data and measurement curves, so that we can realize precise control of the steelmaking process during production.

The system realizes the width measurement of the slab through the line scan cameras installed on both sides of the gantry slab, and the measurement data is transmitted to the host system through the optical fiber. Accurately calculate the actual width of the slab and the width deviation of the slab from the data collected by the linear array CCD camera with up to 8K pixels and the relative position of the double linear array CCD cameras installed on site. Then we can the actual parameter data and allowable deviation parameters of the slab by using the host system software part, so as to realize the alarm control.

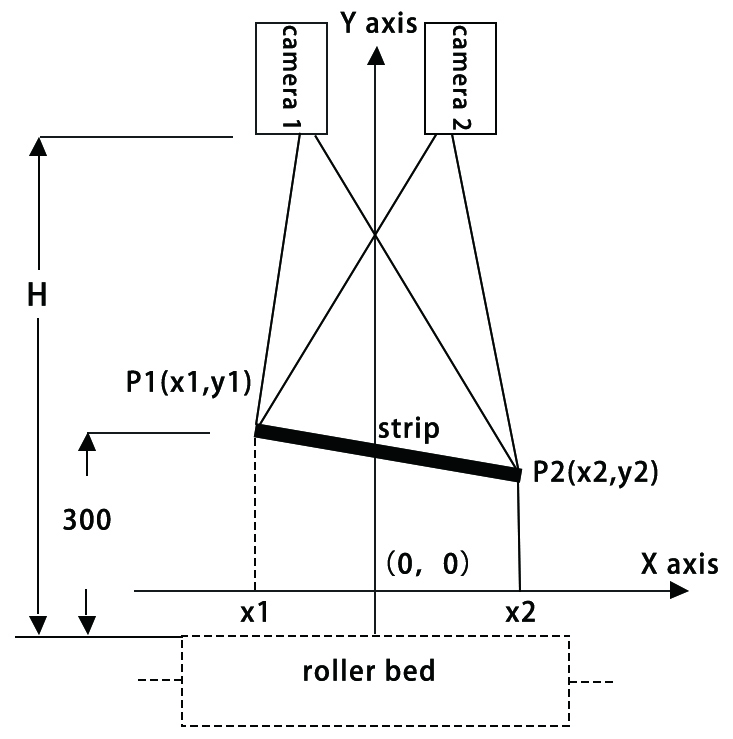

The measuring principle of the system:

The slab/strip width measuring system is mainly composed of a hardware system and a software system. The hardware system includes two line scan cameras which can scan and image for the casting billet, and the arithmetic unit calculates the absolute position and width of the casting billet by the measurement data collected by the line scan cameras. If a color camera is used, the temperature of the slab can be measured at the same time and transmitted to the host system of the width measuring device. The software in the host system calculates the actual width of the slab and the width at room temperature according to the data of the arithmetic logic unit, and displays the relevant data and change curve, then alarm according to the deviation threshold set by the software system or manually. The software system is mainly used to analyze and process the measurement data collected by the hardware system, display the casting billet data analyzed by the software through the display panel, and send control and alarm to the hardware system instruction.

When measuring with a line scan camera, the width measuring device uses two cameras to measure the object at the same time from different angles. The two cameras are like human eyes, which can form stereo vision, so that the sufficient information can be got to judge the distance of the measured object. Correcting and eliminating the effect of distance changes on measurements. From the positions of the two edges of the measured object in the two cameras and geometric derivation, the positions P1(x1, y1) and P2 (x2, y2) of the strip edge in the X-Y coordinate space can be calculated, and the width of the measured object is the straight-line distance between P1 and P2 W=|P1P2|=√ [(x1-x2)^2+(y1-y2)^2]

The features of the system:

It can effectively identify and compensate the beating, inclination, side deflection and profile of the tested plate;

Three-layer high temperature protection of air-cooled, water-cooled and outer interlayer asbestos;

Moving image linear noise correction technology, electronic exposure technology;

With shock-absorbing installation design to reduce measurement errors;

The software has self-diagnosis function;

Full digital detection, automatic calibration system;

Unique optical vibration compensation technology;

High measurement accuracy and fast response;

Using optical fiber signal transmission;

The technical parameters of the system:

Measuring distance: 2m-10m (according to the on-site environment)

Measuring range: 0.05m-40m

Resolution: ±0.01mm

Repeatability accuracy: 0.05mm

Measurement output frequency: 30Hz (adjustable)

Laser class: 2 (IEC60825-1:2014)

Protection class: IP65

Camera pixel: 8K

The measurement range of temperature : 0℃-1200℃

Working temperature: -20℃-60℃

- Model

- WGS-C200

- Country of origin

- China