Egg Tray Machine

Egg tray machine is a great project for both small scale and large scale investors. Beston pulp tray machine can produce 800 to 6,500 pieces of egg trays hourly, which offers more choices for customers. During these years, we have successfully exported our paper egg tray machines to 30+ countries, including India, the Philippines, Indonesia, Russia, Ghana, Dominica, Saudi Arabia, Sudan, Mali, Algeria, etc.

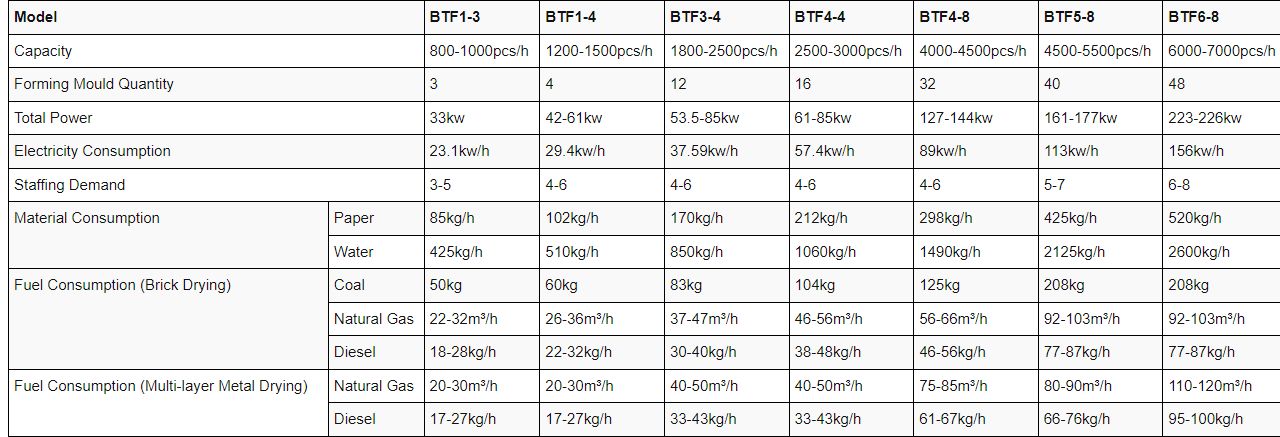

Beston Egg Tray Machine for Sale:

As mentioned, Beston has different models of paper egg tray making machines to choose from, which can produce 800 to 6,500 pieces of egg trays. Let’s review the parameters. And if you want more details or a custom egg tray manufacturing business plan, please feel free to contact us!

How Much Is An Egg Tray Machine?

Beston egg tray machine starts from 10,500 USD. The cost is influenced by the capacity, working method, etc. Welcome to contact Beston for more details.

It mainly depends on the capacity. Generally speaking, the larger the machine, the higher the price. In addition, the automation grade will also influence the cost, which mainly refers to the drying modes. For a small egg tray machine, you can choose natural drying to lower your cost. While we also offer brick drying line and metal dryer to improve working efficiency. More than that, you also need to take the operating cost into consideration, such as fuel consumption, labor force input, space, etc. All you need to do is to choose the one that suits your needs best instead of relying on the cost only. Welcome to contact Beston for more details!

What Will Beston Offer?

1. Fair Egg Tray Machine Price

People always prefer to buy a pulp tray machine from India or China at a lower price. Beston Group Co., LTD. is a qualified pulp molding machine manufacturer in China, which has its own factory and R&D team. So we can offer you quality machines at a factory sale price. More than that, we do exporting for years to save your money and time.

2. Customized Egg Tray Manufacturing Project Report

As shown in the tables, there are different models to choose from. Also, you can choose the drying line, packing equipment, etc. Besides that, you can customize the molds to make egg trays, quail egg trays, egg crates, egg cartons, fruit trays, cup holders, etc. More importantly, we will make a detailed egg tray plant project report according to your real conditions.

3. Stand-alone Machine or Whole Production Line

Pulp molding machine is the core equipment you need, which is automatic and easy to operate. More than that, you also need pulp making machine, which can make waste paper into pulp. If you have a large-scale business, you may also need a dryer or packing machine. Beston can offer these parts individually or together.

4. Full Service

Once you contact Beston for the price list, you can get a reply in 24 hours. You can come to visit our factory and office on site. There is a multilingual team so that you will not worry about the language problem. From pre-sales consulting, through installation, to after-sales tracking, Beston will be there 24*7 a week. Also, we have 8 overseas offices and more than 60 after-sales engineers to respond to you quickly. Anyway, you will never regret cooperating with our company.

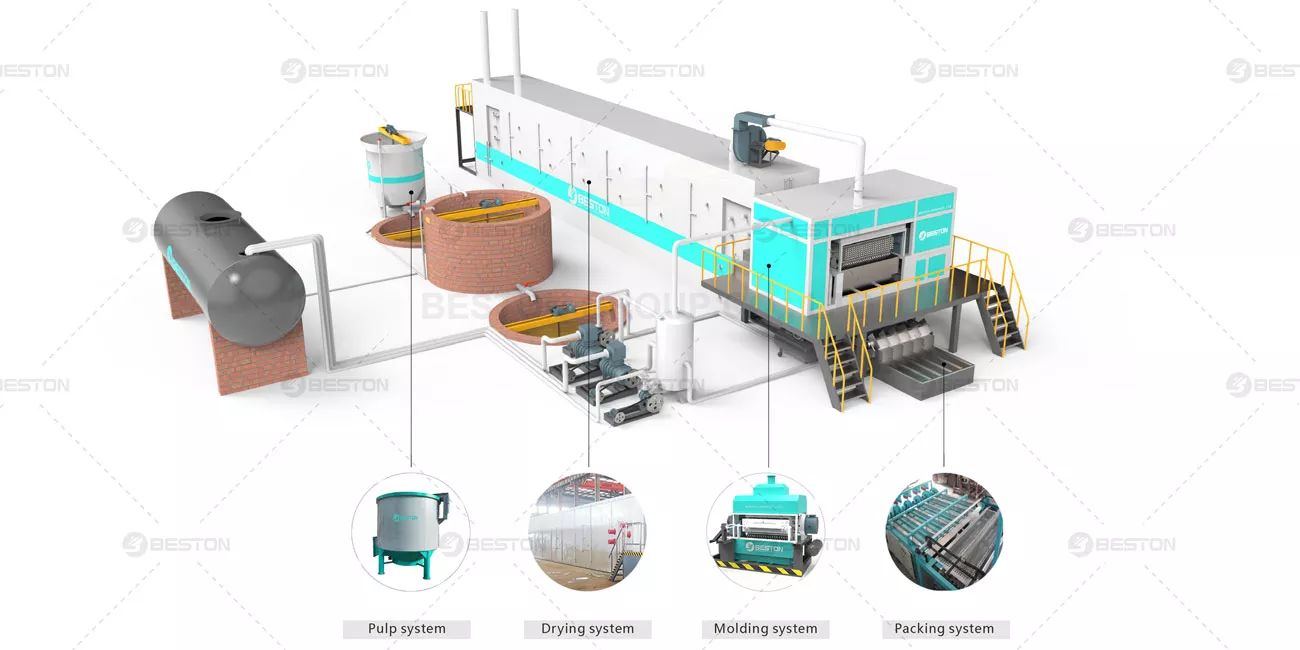

Egg Tray Production Process:

The whole egg tray production line includes pulp making system, pulp molding system, drying system, and packing system.

Pulp Making System:

You can use waste paper, including old newspapers, offcuts, old cartons, etc. as raw materials. This step aims to turn waste paper into pulp. It consists of hydraulic pulper, pulp refiner, and pulp pumps. Besides that, you also need a water pool, pulp storage pool, and a refined pulp pool. For some small-scale investors, we have an integrated pulping system to choose from, which is easy to install.

Molding System:

The main equipment is the pulp molding machine, which makes the refined pulp into different trays. There is also a vacuum pump, which can remove 70% water out of the wet trays. And then the wet trays will be removed from molding dies using an air compressor. Some machines are also equipped with an automatic cleaning device to clean the molding dies after demolding. Beston uses a rotary pulp molding machine, which is automatic and safe to use.

Drying System:

The egg tray dryer machine aims to dry the egg trays. For small-scale egg tray plant, natural drying is recommended, which can greatly lower your investment cost. But it will take more labor force and space. For that, we also have brick and metal drying lines to choose from to improve the drying speed. The brick one needs at least 35 meters in length. If you don’t have enough space, you can choose the metal one, which can be multi-layer design.

Packing System:

This system is an optional section. Some investors would like to pack manually. While some will have an automatic packing system, including counter, packer, etc. You can also buy a hot press, which makes the trays tidy and easy to pack.

FAQs of Egg Tray Making Business

1. What are the uses of egg trays?

Egg trays are used to protect eggs during transportation and storage. It can increase the added value of eggs. Especially, paper egg trays are degradable and recyclable.

2. What is egg tray made of?

Here we use waste paper as egg tray raw materials, including old books, newspapers, old magazines, old cartons, offcuts, used egg trays or egg cartons, etc. It is an eco-friendly business.

3. Is it possible to customize the egg tray mold?

Of course. The common end products include 30-cavity egg trays, 6-shell/12 shell egg cartons, etc. You can also custom the molding dies to make quail egg trays or cartons, nursery trays, fruit trays, coffee cup holders, bottle trays, etc. Also, you can choose plastic or aluminum molding dies.

4. How much space is required for production?

You need to confirm the model first. For the other thing, the egg tray plant space is mainly influenced by the drying system you choose. For example, natural drying requires more space. If you don’t have enough space, you can use a brick or metal drying room. In comparison, the metal dryer is multilayer, which requires less land. Beston will offer you a custom layout design. Below is a 3D layout design of Beston automatic egg tray machine.

5. How to choose a suitable egg tray machine?

Firstly, confirm how many egg trays you will process. For example, if you are a poultry farmer, and you want to make trays for your own use, a small egg tray machine is enough. While if you want to sell trays for business, you can have a large-scale machine. The other important thing is to confirm the mold design, for example, 30-cavity trays, egg cartons, quail egg trays, etc. Then choose an affordable one within your budget. Besides, you also need to take the space, raw materials, labor cost into consideration. Contact Beston, we will help you to find the machine to meet your requirements. Below is a video of Beston egg tray factory, which shows the whole egg tray making process.

- Country of origin

- China