Charcoal Making Machine

Charcoal Making Machine Price:

When you learn about charcoal making machine price, you may also want to know the factors that affect the charcoal maker price, whether it’s profitable to invest in a charcoal machine, and specific ROI analysis report. This article will tell you the answer!

BST Series Charcoal Making Machine Price:

Beston charcoal making machine price is from $30,500 to … According to different working methods and configurations, the price of charcoal making machine is also various. But Beston is confident to offer the most affordable price and high-quality charcoal machines for sale on the market. The most effective way to receive an accurate quote is to tell yus your requirement for reply!

Note: The price is for reference only. Models, raw materials and output will affect the charcoal making machine price. Please contact Beston to get a detailed quotation.

Factors that May Affect Charcoal Making Machine Price:

Raw Materials:

All kinds of biomass waste, such as sawdust, coconut shells, olive shells, palm shells, bamboo, etc. can be used to produce charcoal. The prices of these raw materials vary greatly from different countries. For example, in India and the Philippines, the price of discarded coconut shells is much cheaper than in other countries. It is profitable to choose palm shells for charcoal production in Malaysia. Bangladesh is rich in jute, which is a good raw material for charcoal production. Brazil is rich in sugarcane, if the bagasse can be converted into charcoal, it will be very valuable and so on. Choosing the most cost-effective local raw materials for charcoal production equipment will create huge profits for you.

• Rice Husk

• Rice Straw

• Sawdust

• Wood Chips

• Coffee Husk

• Hazelnut Husk

• Coconut Shells

• Palm Kernel Shell

• Bamboo

• Sugarcane Bagasse

• Peanut Husk

• Sewage Sludge

Final Product Sales:

After the high-temperature carbonization process, customers can get high-value products such as biochar, wood tar, wood vinegar and consumable gas. Every products is useful in many industries.

Biochar:

Biochar comes from fruit shell and is environmentally friendly and pollution-free. It has the advantages of fast burning, high calorific value, smokeless and tasteless when burning, which is the best choice for barbecue charcoal. After processing can make shisha charcoal, activated charcoal and other products. Biochar is a good soil conditioner. Mixing biochar into soil can reduce soil acidity, improve soil structure, and promote the growth of plants and crops.

• Charcoal Blocks

• Charcoal Powder

• Charcoal Briquette

• Make Hookah Charcoal

Wood Vinegar:

Wood vinegar has been widely used in agricultural production in the United States, Japan, South Korea and other countries. Mainly used to promote crop growth and control nematodes, pathogens and viruses. The other half is used in food processing, medicine and health care. Japan has developed a “forest vinegar” beverage using wood vinegar. South Korea has used refined wood vinegar for medicine. The application of wood vinegar in Taiwan also started early, and it has been widely used in the fruit industry, the promotion of crop growth, and the prevention and control of pests and diseases.

Wood Tar:

In most cases, it is used after separation and purification by the coal tar industry. Under normal temperature and pressure, its products are black viscous liquid, and various fractions can be further processed to separate a variety of products, such as mothballs, asphalt, plastics, pesticides, etc.

Consumable Gas:

The charcoal reactor generates exhaust gas during its operation. After being dedusted and purified, the exhaust gas becomes combustible gas and enters the exhaust combustion chamber. This hot gas can save 15% of fuel costs for charcoal machine investors.

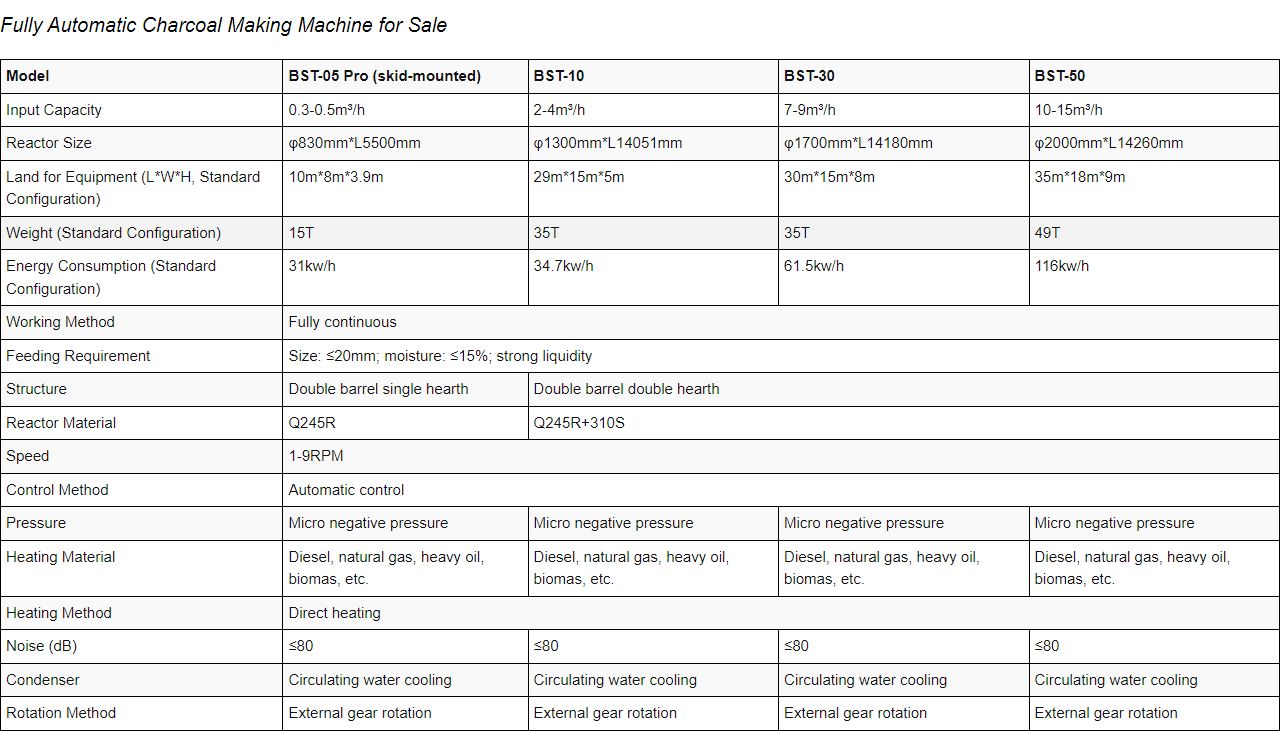

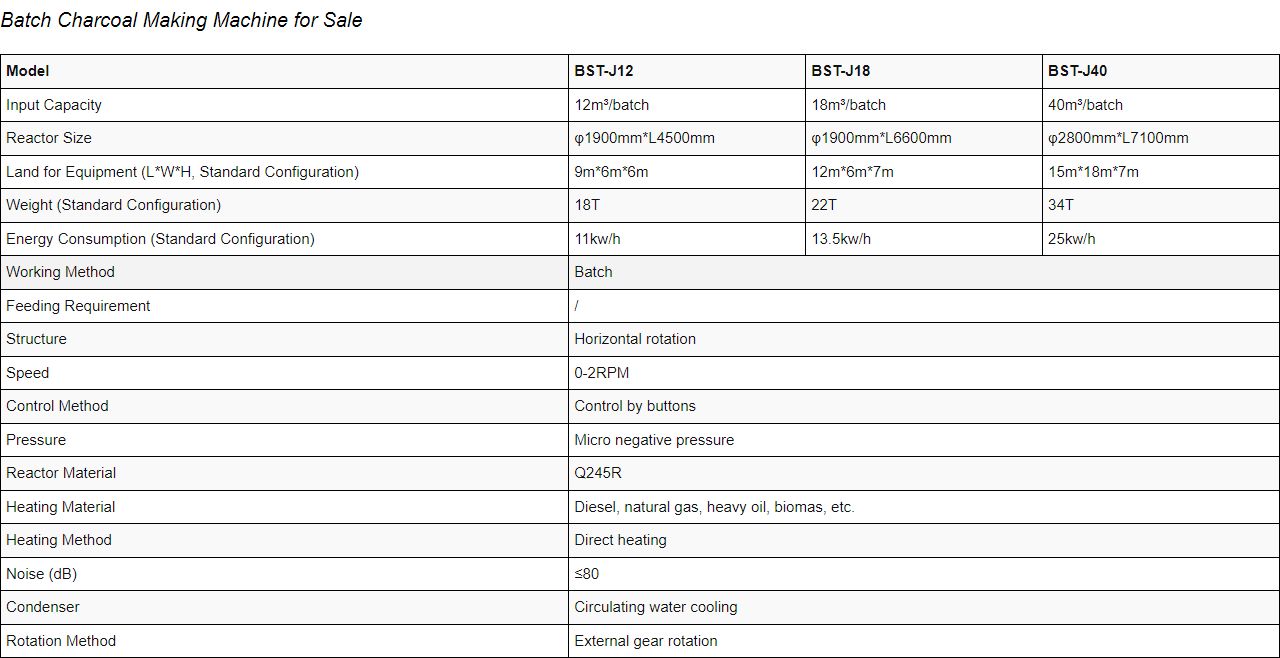

Beston Charcoal Making Machine for Sale:

Each of Beston biochar equipment for sale has the advantages of high efficiency, energy saving and easy operation. This equipment embodies the hard work of Beston engineers for many years. We are committed to turning waste into treasure for customers in an environmentally friendly way. According to the degree of automation, we can be divided into automatic charcoal making machines and batch charcoal making machines.

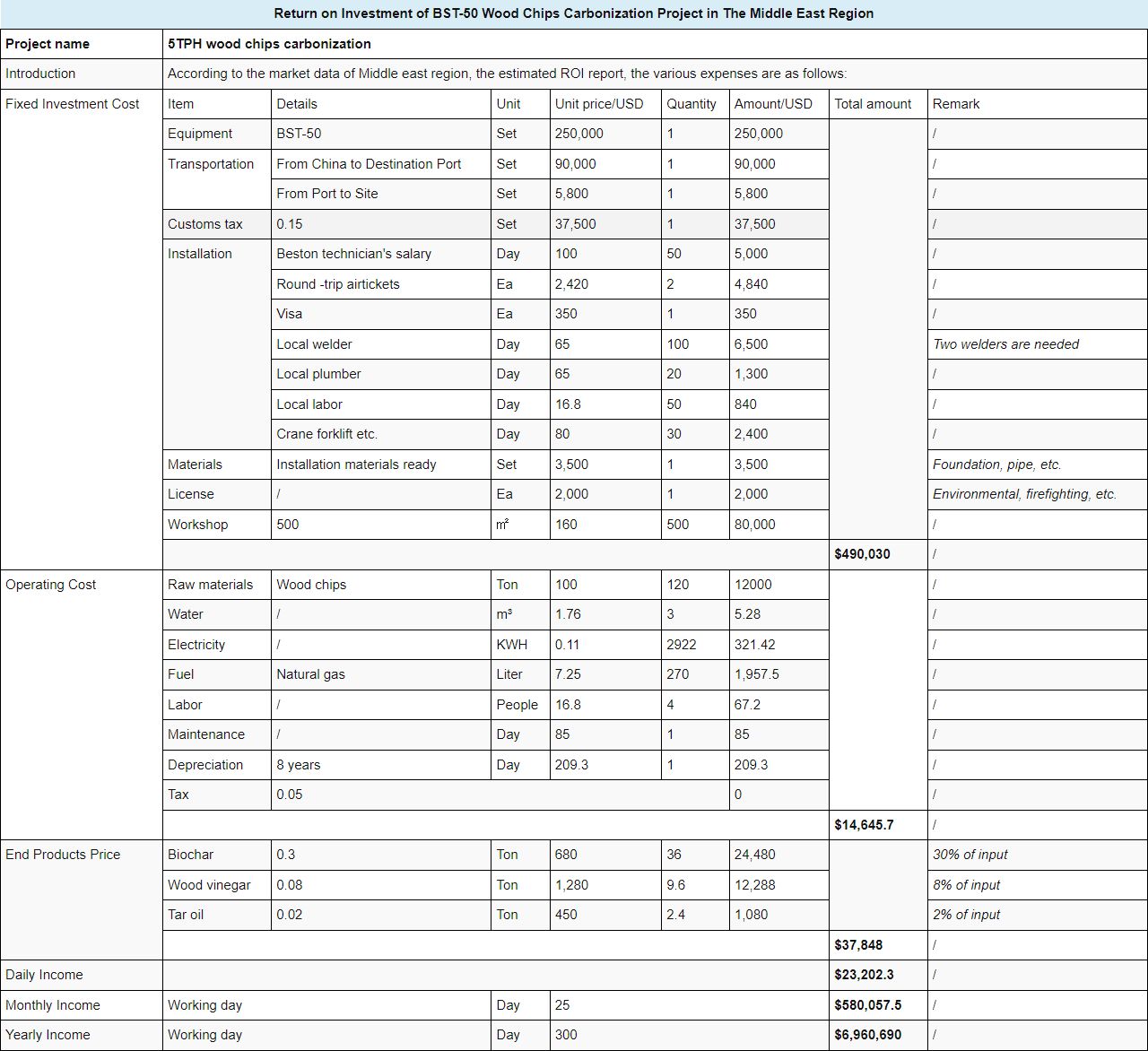

Is It Profitable to Invest in Beston Charcoal Making Machine?

Yes! Beston charcoal making machine is profitable in most places of the world.

First of all, the final products are in short supply in the market. Whether sold directly or processed into other products, biochar, wood vinegar and tar have high economic value. After investigation, the prices of these products have been showing an upward trend in many countries. So it’s the best time to invest in this machine!

The carbonization of biomass is very conducive to improving the ecological environment. As one of the Serbian customers’ feedback, they can receive about 200 euros to process 1 ton of waste biomass. In addition, local government support such projects strongly. Charcoal manufacturing is an industry with great potential. Now is a good chance to invest in Beston charcoal manufacturing machine.

Additional Value Included in Beston Charcoal Making Machine Price:

Beston enjoys a certain reputation in the international market. Whether charcoal making machine price, quality or service, Beston is in a leading position in the industry.

Beston Quality:

Beston environmental protection products are sold to more than 50 countries and regions, including Malaysia, Turkey, Cote d’Ivoire, India, U.K, Cameroon, Thailand, Ghana, Venezuela, Indonesia, UAE and so on. All of the coconut shell charcoal machines from Beston have passed ISO international certification. So customers can buy with confidence. Beston has a large-scale factory covering an area of more than 15,000 square meters and more than 500 employees. We have a strict quality inspection system to ensure that we provide the best charcoal making machines for customers all over the world.

Beston charcoal making machine adopts closed production. The carbonization furnace is equipped with explosion-proof devices, multi-point pressure and temperature monitoring points, etc.. These measures aim to ensure the safety of charcoal manufacturing in a variety of ways. Beston charcoal making machine runs very smoothly with almost zero error rate, which greatly reduces subsequent maintenance costs.

Beston Service:

Beston 8 professional departments provide you with a full range of services. From project consultation to equipment production and delivery, we will do our best to satisfy customers. At pre-sales stage, progject managers provide you with one-to-one consultation and customization. Their rich experience and professional knowledge can provide you with localized services. And the after-sales team will keep you updated with the latest progress on the production and delivery of the charcoal machine for sale. At present, due to the impact of the epidemic, many overseas customers cannot visit the Beston factory in person. But they still choose to work with us. Because they believe in Beston quality.

- Country of origin

- China