ZHR Rubber Slurry Pump

ZHR rubber liner slurry pump is ideal solution for convey water and solid mixture medium. Suitable for conveying fine particles and corrosive liquids that contain suspended particles. The ZHR series slurry pumps have the features on replaceable wear-resistant metal liners. Basing on medium condition can choose different materials of Natural rubber, Nitrile rubber, Polyurethane etc.

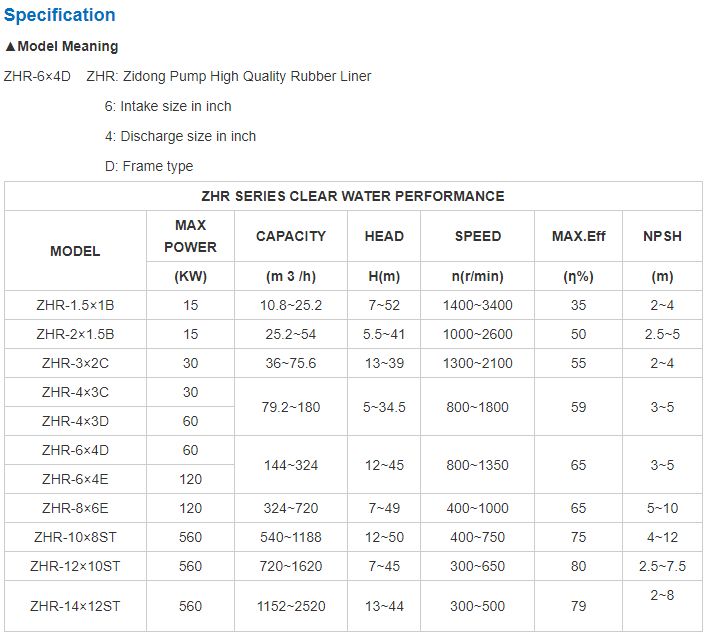

Capacity Range: 10-2500 m3/h

Head Range: 7- 50m

Speed Range: 300-3400rpm

Power Range: 15-560kw

Zidong Pump (Brand Name) ZHR rubber liner corrosion resistance mineral slurry pumps are single-stage, cantilevered, double casing, horizontal, centrifugal slurry pump.

They were designed for handing corrosive, acid or erosion slurries in mining, coal, metallurgical, power, building material, sand washing and other industrial departments.

This series of pump guarantees excellent performance including wear resistance, chemical resistance, waterproof and higher operating temperature range from -40-75.

The wear parts are made of material natural Rubber ZR26, ZR55, ZR33. And more, OEM material is available, eg. ZR08, ZS42, ZS10, ZS12, ZS01, ZS02, ZS21, ZS31, ZU03, ZU27 etc,

In view of the features on replaceable wear-resistant metal liners, the pump has variety of combinations of lining and impeller to adapt to different media characteristics.

Features:

1. Modular design, easy to maintain, low spare cost due to high standardization;

2. Wide options of impellers of standard closed 5vanes, open 3vanes non-clogging;

3. 27% Chrome alloy hard metal, thick rubber and polyurethane pump lining are available and can be replaced with each other;

4. Standard ductile iron pump body, can withstand higher working pressure;

5. Famous brand bearing components can improve reliability, prolong bearing life and reduce lubrication cost;

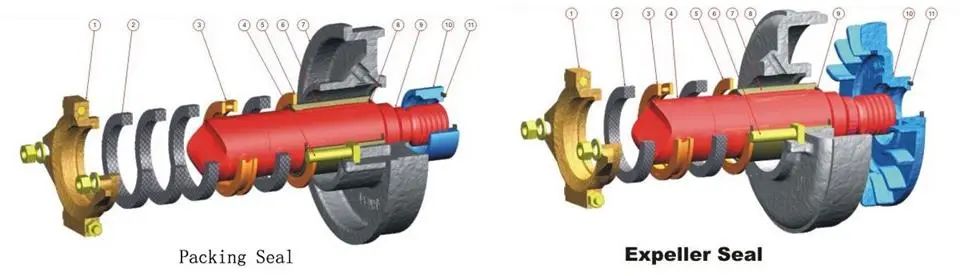

6. Reliable shaft seal, packing seal, expellerseal, or mechanical seal are available.

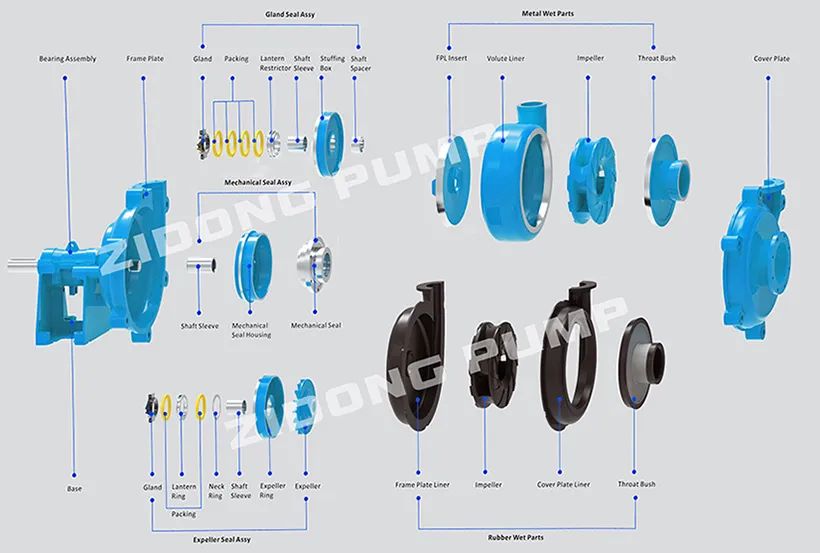

Structure:

Composition characteristics:

1. Its pump body, pump cover and transmission parts are interchangeable with ZH, ZM, ZHH pumps.

2. Interchangeable anti-corrosive wet parts made of natural rubber or other customized elastomer materials;

3. Various drive types: DC(direct connection), V-belt drive, gear box reducer, hydraulic couplings, VFD, SCR control, etc;

4. The shaft seal uses the packing seal, expeller seal and mechanical seal

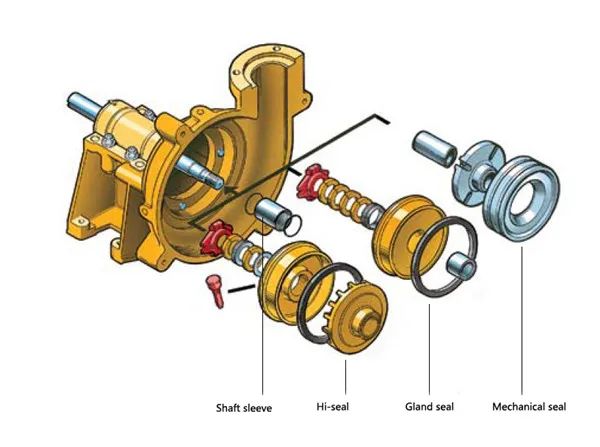

A hardened, heavy duty corrosion-resistant sleeve with "O" Ring at both ends protects the shaft.

A slip fit allows the sleeve removed or installed quickly.

Glandseal--A packed gland type shaft seal is also available and can be fitted with a low or full low flush seal water arrangement.

Expeller seal- A large percentage of duties allow the use of expeller seal which eliminates theneed of sealing water.

Applications:

They were designed for handing corrosive, acid or erosion slurries in mining, coal, metallurgical, power, building material, sand washing and other industrial departments.

• Mineral processing

• Ash handling

• Cyclone feeds

• Chemical slurry service

• Coal preparation

• Effluent handling

• Wet crushers

• Aggregate processing

• Ball mill discharge

• SAG mill discharge

• Rod mill discharge

• Fine primary mill grinding

• Tailings

• Secondary grinding

• Waste sludge

• Phosphoric acid

• Pulp and paper

• Food processing

• Cracking operations

• Industrial processing

- Model

- ZHR

- Country of origin

- China