Food End Line

Stolle machines produce more full-open ends for food cans that any other make of machinery around the world. As a technology leader, Stolle provides proven equipment with the latest engineering advancements as well as OEM parts, service and rebuild services from facilities around the globe.

Food Shell and End Systems:

Stolle single-action rotary curled (SRC) shell and end systems can be configured to produce any type of round food end from steel or aluminum, including shells for easy-open end conversion or finished sanitary ends. Our wide or narrow coil-fed systems can produce ends from 113 to 209 diameter, and our sheet-feed systems can produce shells and ends from 200 to 401 diameter. All Stolle systems feature our exclusive “Reverse Form” single-action tooling, air shell conveying, and our TEC-240 external rotary curlers. These unique features allow Stolle SRC systems to offer the industry’s lowest tooling costs per 1000 shells, maximum shell consistency and easier set-up and maintenance.

Rotary Compound End Liners:

Stolle VHSL and HSL rotary liners are available with 4, 6 or 8 applicators for applying sealing compound to food ends from 200 to 603 diameter with maximum efficiency. The most widely used compound liner in the world, the Stolle VHSL Liner has independent variable-frequency drives for the applicator turret and lower chucks that can adjust to varying line speeds. For endmakers who produce one end size at a constant speed, the economical HSL Liner uses a single drive for the lower chuck and turret drive. Both machines are available for applying water or solvent-base compound, as well as plastisol compound for lining lug caps. A unique triple-screw downstacker ensures that larger diameter ends (above 307) are evenly supported and fed smoothly into the starwheel with no marks or scratches. Stolle also offers a full line of liner support equipment, including compound supply systems, conditioning systems for solvent-base compound, and a nozzle brush cleaning system for water-base compound.

Full Open End Conversion Systems:

Stolle food end conversion systems provide adaptable and flexible solutions for converting steel or aluminum ends in a variety of sizes, shapes and metal thicknesses. We build systems to meet different production requirements, including the high volume 4-lane Mega 4 and the 3-lane Mega 3 systems. The lower volume Mega 2H system can be configured to run round ends as well as square, rectangular, oval, ¼ club and ¼ Dingley shapes. Food system customers also benefit from Stolle’s continuing technical innovations for full open ends, including rivet designs for single-reduced (SR) and double-reduced (DR) steel ends, a more consumer-friendly and metal efficient food end tab that offers reduced pop and pull force for both SR and DR steel ends.

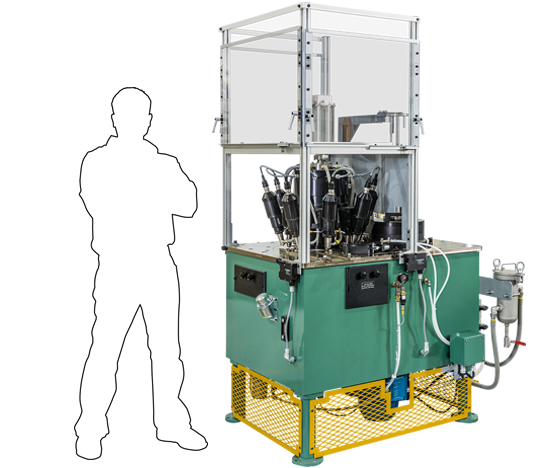

PostOp Score Repair System:

The Stolle PostOp System applies a food-safe coating material to the score line and tab rivet head on round steel food ends from 202 - 401 to protect the exposed base steel. On both critical areas, the coating application eliminates the possibility of rust or corrosion that could negatively impact consumer appeal. The most productive score repair system available, the Stolle PostOp has two lanes that operate at 500 EPM each for a total throughput of 1000 EPM – equivalent to many two-out full-open end conversion systems. The PostOp system includes a reliable Stolle high speed end transfer system, coating spray system and a vertical gas-fired curing oven. Stolle’s innovative new servo-driven oscillating spray head uses two nozzles that each coat half the end at half the speed as a single nozzle spray head, which reduces coating usage, maintenance and overspray. A complete end size changeover can usually be accomplished in less than one shift.

- Brand

- Stolle

- Country of origin

- United States