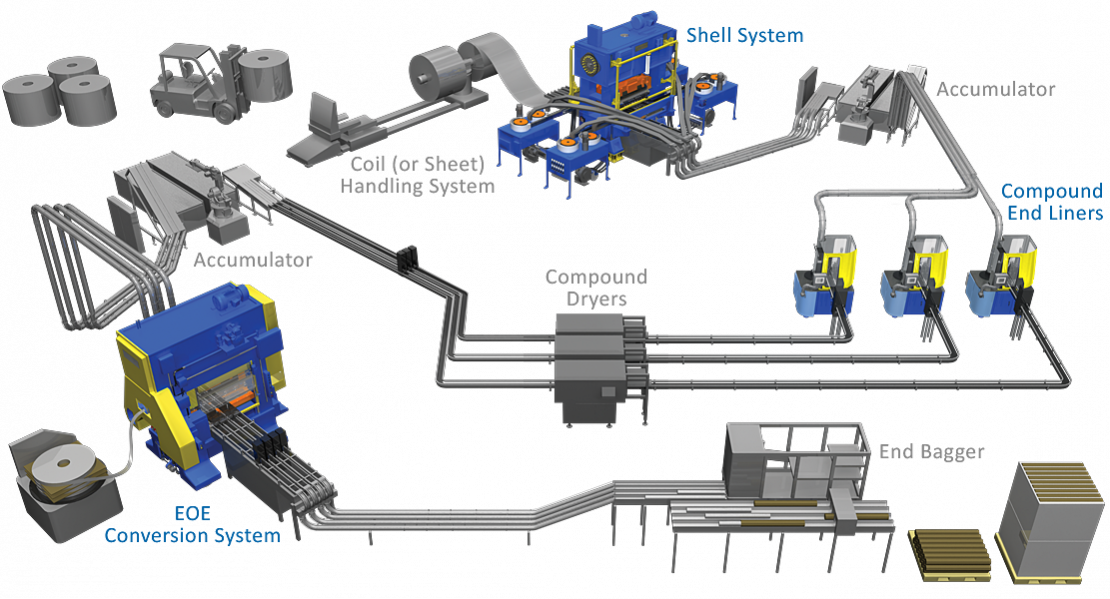

Beverage End Line

Stolle machines produce more easy-open ends for beer/beverage cans that any other make of machinery around the world. As a technology leader, Stolle provides proven equipment with the latest engineering advancements as well as OEM parts, service and rebuild services from facilities around the globe.

SRC Shell Systems:

Wide Shell: For high volume beverage end production, Stolle can design and build a wide coil shell system to meet your specific beverage end requirements. Our wide systems have from 10 to 28 die pockets, production speeds up to 450 SPM, and can produce up to 12,600 shells per minute.

Narrow Shell: For lower volume beverage end production, Stolle can design and build a narrow coil shell system to meet your specific beverage end requirements. Our narrow systems have from 1 to 9 die pockets, production speeds up to 700 SPM, and can produce up to 6,300 shells per minute.

Rotary Compound End Liners:

Stolle Liners apply sealing compound to shells and ends with maximum speed and efficiency.

The Stolle Vortex Liner can accommodate up to 10 compound applicators and can produce up to 2600 EPM – a 25% production increase in the same floor space as other liners. This greater throughput makes it possible to eliminate one liner in a high volume beverage end module. Stolle VHSL and HSL Liners are the world's most widely used liners, and can be equipped for beverage and food ends in a wide range of diameters.

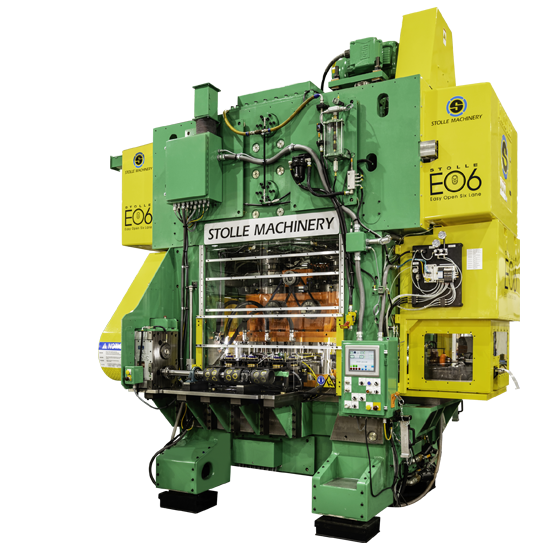

Easy-Open End Conversion Systems:

Stolle high speed conversion systems are the first choice globally for producing easy open ends for beer and beverage cans.

Stolle high speed conversion systems are the choice of canmakers around the world for producing easy open ends for beer and beverage cans. Introduced in early 2020, Stolle’s new six-out EO6 system features a new design 140 ton press that operates up to 850 SPM to produce an astounding 5100 EPM. It features three 2-out lane dies and a new design 6-out tab die. The 4-out Stolle Tetrad is the world’s leading EOE conversion system, producing up to 3000 ends per minute, while the 3-out System H produces in excess of 2100 EPM. Both of these systems use an industry-proven 125 ton single-action press that operates at speeds of 700+ SPM (depending on end size). Timely tooling design updates guarantee that a Stolle conversion system will provide leading edge EOE technology, providing customers with efficiency, economy and increased consumer value.

- Brand

- Stolle

- Country of origin

- United States