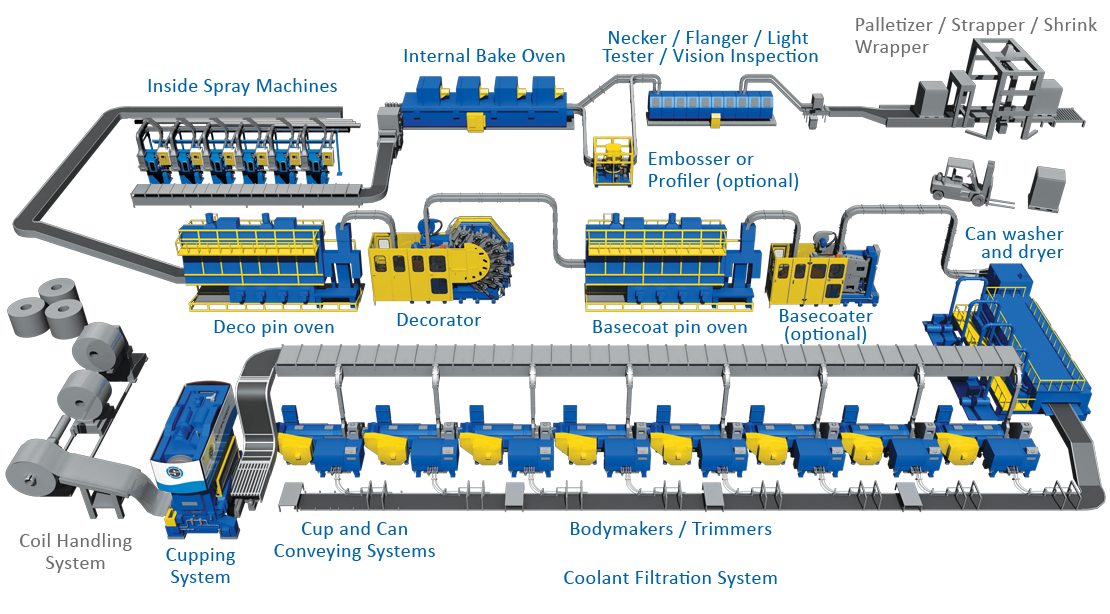

Beverage Can Line

Stolle Machinery is the world’s leading supplier of machinery for the production of two-piece can bodies for beer and other beverages. As a technology leader, Stolle provides proven equipment with the latest engineering advancements as well as OEM parts, service and rebuild services from facilities around the globe.

Cupping Systems:

DynaForm: Quality 2-piece can bodies begin with quality cups, and Stolle cupping systems produce the highest quality cups with maximum speed, reliability and material efficiency.

For high volume can plants, the Stolle DynaForm cupper is capable of speeds of 300 SPM or higher, depending on cup size and configuration. The 165-ton high speed press features the latest ram guidance technologies that extend tooling life and reduce operating costs. A ram quick-lift feature provides easy tooling access, and optional magnetic die clamping make cupping die changeovers faster and easier.

Triton: Quality 2-piece can bodies begin with quality cups, and Stolle cupping systems produce the highest quality cups with maximum speed, reliability and material efficiency.

The Stolle Triton cupper is the most widely used and trusted cupping system in can plants around the world. It features a reliable 150-ton double action press, and optional magnetic die clamping make cupping die changeovers faster and easier.

DWI Bodymakers:

Standun: Stolle Standun and Ragsdale Bodymakers lead the industry in the production of two-piece DWI can bodies.

Standuns can be found in more can plants than any other bodymaker machines. These specialized horizontal presses are engineered to maintain the extremely close tolerances required in finished can bodies, and are ruggedly built to deliver a quality product day after day. Standun Bodymakers are available in a range of stroke lengths and tool pack sizes for producing aluminum and steel can bodies in sizes from small juice cans to tall aluminum bottle preforms and 2-piece aerosol cans.

Ragsdale: Stolle Standun and Ragsdale Bodymakers lead the industry in the production of two-piece DWI can bodies.

The Ragsdale has a long history of reliability and precision, which is why they are the preferred bodymaker of so many canmakers. Available in five stroke lengths with production speeds from 225 to 375 cans per minute, the Stolle Ragsdale® bodymaker produces aluminum and steel beverage or food can bodies with superior accuracy and productivity. Features include an improved fluid bearing ram, the Diamond Linkage to assure accurate ram travel, and a servo cup feed and can unloader.

Coolant Filtration System:

The Stolle Coolant Filtration System can process up to 660 gallons of coolant per minute to accommodate up to 20 bodymaker machines. It features two carbon steel pressure vessels with advanced design, high flow filter cartridges that feature a cleaning cycle of about 30 minutes from depressurization to restart. The system is designed as a modular package incorporating coolant reservoirs, filters, pumps and controls, all mounted on a smaller footprint base for economical transport and easier installation.

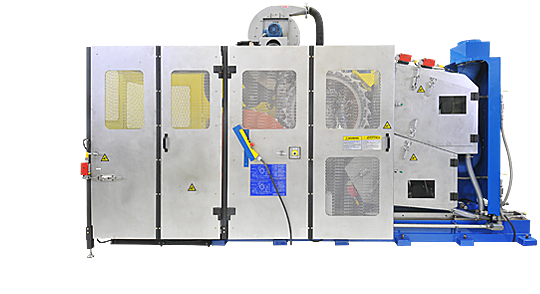

Stolle Trimmer:

The Stolle Trimmer features an updated design that trims DWI cans and bottle preforms in sizes up to 10” high with stationary can pads and trimming heads that move the knives to the cans. Keeping the can bottoms in the alignment to the bodymaker domer allows simpler and more reliable crossover trackwork, and the sliding base design allows the 3 trimming heads to be easily repositioned for different can heights with no change parts needed.

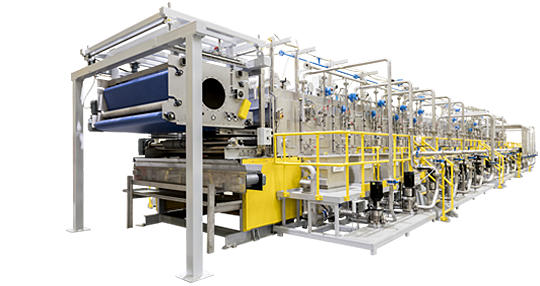

Optimus Can Washer:

The Optimus Can Washer thoroughly cleans and treats the surface of aluminum or steel beverage can bodies upon discharge by the bodymakers/trimmers. The multi-stage machine has wash, rinse and treat sections, and can be custom-built with other sections and features. The Washer has a number of water, chemical and energy saving features, and is solidly constructed of premium materials for long service and easy maintenance.

Optimus Can Dryer:

Designed to mate on the discharge end of an Optimus or other make of can washer, the Optimus Can Dryer completely and efficiently dries cans with heated forced air. It features a suction-type impingement recirculating air system which allows for a high heat transfer rate, while maintaining can stability via vacuum throughout the heating zone. The results are a compact drying package with reduced dwell times, reduced operating temperatures and smaller overall footprint.

Basecoaters:

For beverage label branding that requires basecoated cans, Stolle Concord and Rutherford Basecoaters apply a solid opaque coating to can bodies in preparation for decorating at speeds up to 1800 CPM. Both machines have dual coating units with independent speed controls that produce highly accurate coating weights and a superior can finish with minimal overlap and slinging.

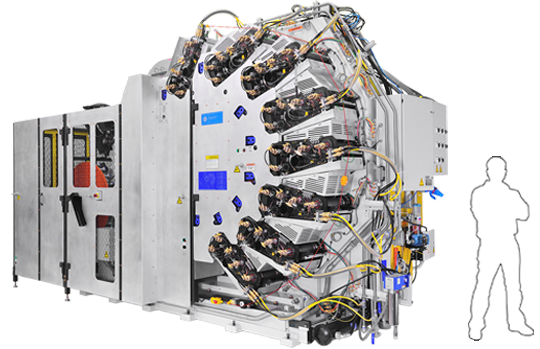

Decorators:

Concord: Stolle Concord and Rutherford Decorators are the industry’s leading machines for high speed, high quality decoration of 2-piece beverage cans.

Concord Decorators are the industry’s most popular machines for printing 2-piece cans. They feature 8 ink stations plus varnish for maximum production flexibility, and have many design features that speed label and can size changeover and reduce maintenance. The Concord’s exclusive Rotary Trip mandrel system increases production speeds up to 2200 CPM and reduces spoilage by ejecting only defective cans without interrupting production.

Rutherford: Stolle Concord and Rutherford Decorators are the industry’s leading machines for high speed, high quality decoration of 2-piece beverage cans.

For nearly 50 years, Rutherford Decorators have been trusted fixtures in can plants around the world, and these rugged machines set the standard for high quality, high speed can decoration. Stolle now offers a 9-color system with new design High Performance Inkers, as well as a special “tall” version for decorating aluminum bottle cans and tall aerosol cans up to 10.5”H.

DecoCure Oven:

The Stolle DecoCure Pin Oven cures the external coatings on 2-piece beverage cans immediately after they exit a basecoater or decorator machine. This specially-designed oven is designed to thermoset the coatings in less than 10 seconds with superior temperature uniformity and can stability throughout. High efficiency recirculation fans provide air delivery through U-shaped nozzles which follow the serpentine chain path throughout the heating zone, which ensures an optimum heat transfer rate and a low temperature differential between the upper/lower sidewalls.

Inside Spray Machines:

Stolle inside spray systems apply a coating to the inside surface of two-piece can bodies at high speed and with maximum production efficiency. Stolle offers 2 models that feature Reynolds inside spray technology: the DG-250 (dual gun) has two spray guns to coat the inside of the can, while the TG-350 has a third gun to spray the can dome. Designed primarily for steel cans, the TG-350 passes cans to a vacuum turret wheel that holds the can in place for the dome spray, limiting potential can damage and overspray.

InterCure Oven:

The Stolle InterCure Oven cures the internal water-based coating of 2-piece beverage cans after they are discharged by the Inside Spray Machines. The oven also finishes curing the ink and varnish on the exterior of the cans resulting in fully cured cans that are ready for the final steps of production. The InterCure Oven features a 3-zone configuration (plus an optional cooling zone) that allows for full flexibility in the curing process, next generation gas burners that reduce energy consumption, and has superior temperature uniformity of +/- 2° C.

Embosser and Profiler:

These specialized machines are designed to add tactile patterns to the sidewall of DWI beverage cans for enhanced brand awareness.

The Stolle Registered Embossing Machine embosses patterns in the can sidewall that register with the printed decoration. The Stolle Profiler Machine embosses vertical flutes in the can sidewall. These tactile patterns improve the product’s brand name recognition and create a competitive advantage over traditional aluminum or steel cans.

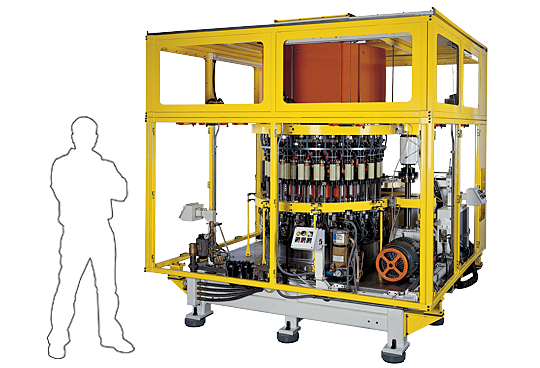

E-NCKR Die Necking:

The new Stolle E-NCKR machine represents another milestone in Stolle’s complete line of value-added can production equipment.

This modular machine is designed to neck 2-piece cans to accept a specified diameter end. In addition to necking, the machine can be equipped with modules to perform other processing functions on the cans, including flanging, base reforming and light testing. The Stolle E-NCKR can also be equipped with infeed and discharge vision inspection systems to perform 100% inspections of cans within the machine.

Conveying Systems:

Stolle designs, manufactures and commissions conveying systems for each step in the can line.

These conveyors include cup discharge air tables, recirculation cup systems, bodymaker infeed sweeps, trimmer discharge tracks and wet can conveyors, washer infeeds, washer discharge turnover units, bright can bi-directional accumulation conveyors, decorator infeeds, spray infeeds, spray discharge and IBO infeeds, necker infeeds and discharges, vacuum transfer units and mechanical conveying for finished cans. All Stolle Conveying Systems products are custom-engineered and are built with the highest quality materials for long life and reliable operation in a can line environment. Stolle also provides conveying systems for 3-piece cans, can ends, PET containers, magnetic conveyors and elevators, as well as conveyors for specialized food processing applications.

- Brand

- Stolle

- Country of origin

- United States