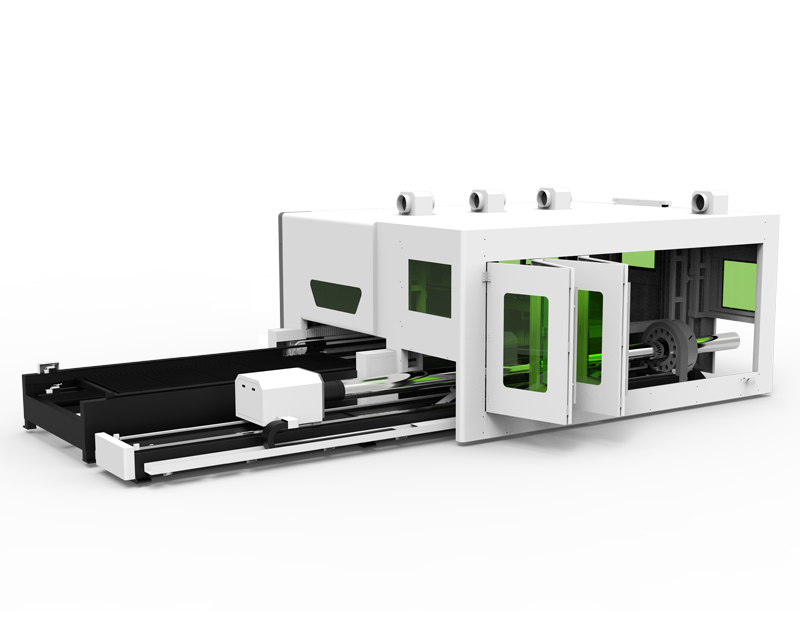

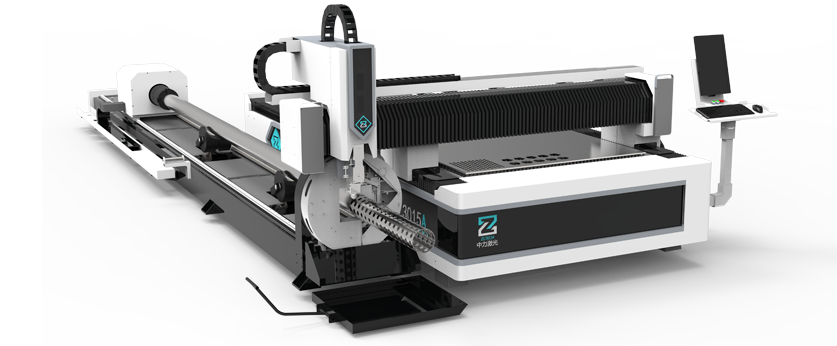

Enclosed Sheet & Tube Metal Fiber Laser Cutting Machine with Protective Cover and Exchange Table

This fiber laser cutter includes protective cover, exchange platform, sheet & pipe laser cutting. Multi function with simple operation, guarantee the safety and great working efficiency.

Different cutting thickness need different laser power, please tell us your materials, size and thickness, then we will recommend you suitable model and power.

Features:

One machine with dual functions ( plate cutting + tube cutting ). This machine = 1 sheet metal laser cutting machine + 1 tube metal laser cutting machine. It will save your purchasing cost and transportation cost.

1. Automatic Exchange Platform

Two platform can exchange automatically at same time within 20S, which improve working efficiency greatly.Stable and reliable transmission mode.

2. Protective Cover

Adopts full enclosed protective cover, which can prevent laser from hurting people. The built-in smoke purification system will avoid avoid environmental pollution and protect the health of operators.

3. Automatic Focus Cutting Head :

Laser head with automatic focus function, which can adjust the focus automatically, no need to adjust it by hand. It can shorten the perforation time, improve the perforation quality and cutting speed.

4. Intelligent CNC System :

Easy to operate even by green hands. It support multiple graphic files include DXF, PLT, DWG, AI, G-code, IGS (tube cutting). It is compatible with other nesting software.

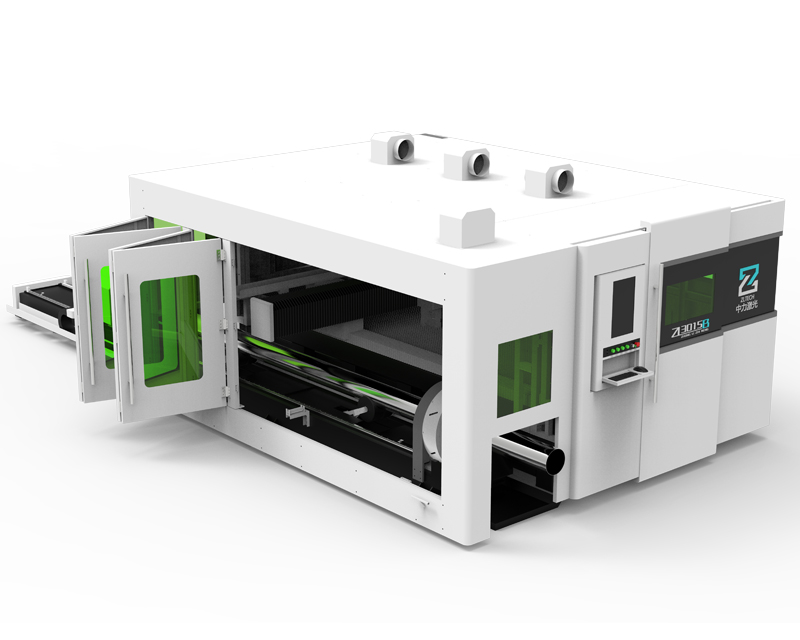

Full Protective Cover:

Adopts full enclosed protective cover, which can prevent laser from hurting people. Also it equips with automatic dust collection system, the cutting dust can be filtered internally and discharged under certain standard, making the process more eco-friendly and no pollution. The front and back of the protective cover are equipped with built-in cameras, Intelligent monitoring system, real-time intelligent monitoring, reducing the incidence of accidents.metal protective cover, safe production.

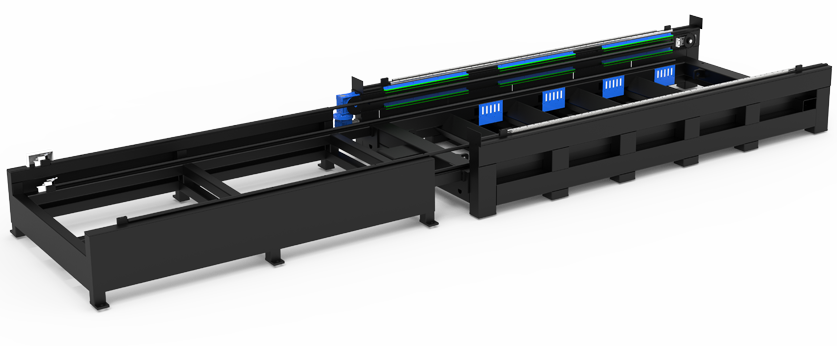

Stable & Strong Welded Steel Bed:

The bed is welded with big thickness square tubes, which has stiffeners inside to increase the structure strength and tensile strength.

With high temperature annealing and natural aging, the welding stress is eliminated, which can prevent the deformation of the bed , reduce vibration and guarantee a good cutting accuracy.

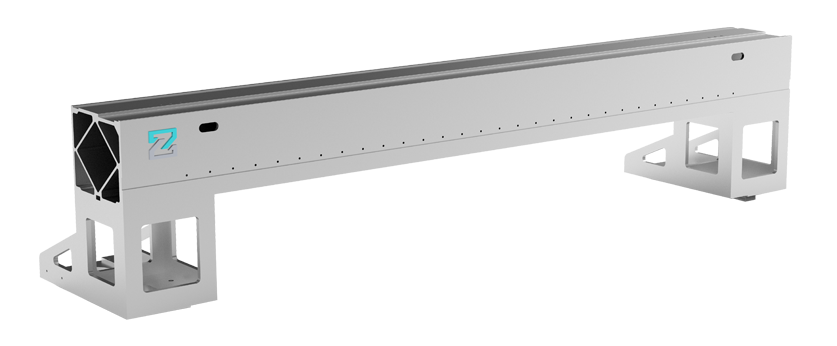

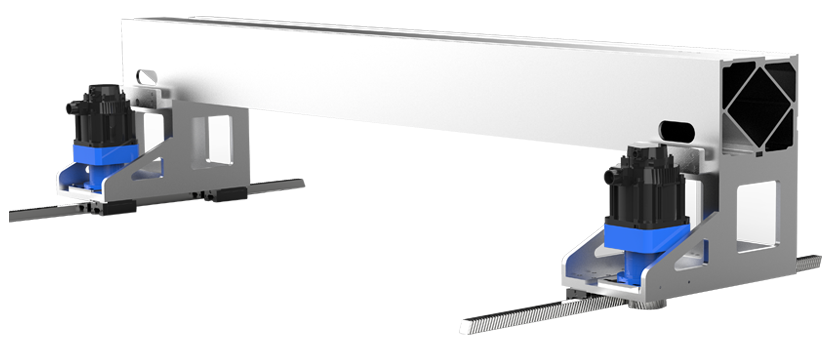

Aviation Cast Aluminum Beam:

Machine adopts aviation cast aluminum beam, which is manufactured according to the aerospace standards and extruded with 4300 tons pressure. The beam is processed by T6 heat treatment which can make the beam obtain the highest strength and strong deformation resistance.

Using ultra-high pressure tensile technology and light weight design, the beam weight is reduced by 30% compared with cast aluminum beam and the strength and rigidity are increased by more than 20%. It’s more convenient for high speed movement and it can greatly increase the processing speed.

Automatic Focus Cutting Head:

Laser head with automatic focus function, which can adjust the focus automatically, no need to adjust it by hand. The software can change the focusing lenses automatically according to the different thickness of the materials. It can shorten the perforation time, improve the perforation quality and cutting speed. It’s simple, convenient and fast.

Full-circle water cooling around the focusing component, which can realize no heat, no fog with high power cutting, small volume cutting and long term cutting, the lifetime of the cutting head is improved greatly.

Fast and Stable Drive System:

Adopts Japan Yaskawa motor, Japan Fuji motor or Taiwan Delta motor, with high precision, no step losing, high torque and low noise.

Adopts Taiwan YYC / Germany HERION gears and Japan Shimpo / France MOTOVARIO / Germany Lead-motion reducers, which can make the machine position accuracy reach to 0.02mm

Independent Control Cabinet:

We put all electrical components and laser source into the independent control box, it is dust proof which can guarantee the life span of the components.

The control cabinet is equipped with air conditioner which can keep the constant temperature automatically. It can prevent the high temperature damage for the components in summer.

Intelligent Operation Software:

Adopts high definition toughened glass, intelligent touch, fast response and smoother operation. Ultra low power consumption and high resolution.

The new intelligent alarm system is pushed to the interface through the control center to find abnormalities in advance, quickly eliminate and feed back, reduce hidden dangers, and there is no danger in remote alarm operation.

One Machine with Two Functions:

-- One machine with two functions : Sheet metal cutting + Tube metal cutting.

--Full automatic double pneumatic chucks

High Efficiency Exchanging Table:

Adopts high-speed parallel exchange table design, dual working table exchange at the same time, stable and reliable transmission mode. Fast, shorten the exchange time, save the loading and unloading auxiliary time. Exchange motor controlled by frequency converter, can finish the table exchange within 15S.

Equipped with hexagonal steel track, the pulley fits with the track closely, strong pneumatic tightening and the built-in pulley runs smoothly.

Double Pneumatic Chucks

2~3 times faster than traditional electric chucks.

2 rows of rollers are adopted for a wide range of clamping and high cutting precision.

Dual support frame for 6m tube.

Φ20-220mm □20-150mm Diagonal: 20-150mm

Parameters:

Model: ZL3015BDC, ZL4015BDC, ZL6015BDC, Zl4020BDC, ZL6020BDC, ZL6025ABDC

Working Area(L*W): 3000×1500mm, 4000×1500mm, 6000×1500mm, 4000×2000mm, 6000×2000mm, 6000×2500mm

Effective Round Tube Cutting Diameter: φ20-φ210mm

Effective Square Tube Cutting Diameter: □20-□150mm

Tube Length: 6000mm

Laser Power: 1000W-20000W

Repeat positioning accuracy: ±0.02mm

Maximum speed: 120m/min

Acceleration: 0.8G/ 1.0G / 1.5G / 2.0G

Power consumption: <10KW

Application:

Cutting Materials:

Sheet Metal & Tube Metal ( round, square and rectangular tubes, profiles like channel, angle and H-shaped steels also it can cut special-shaped tubes easily like triangular, concave, Land C-shaped tubes, etc.

This sheet & tube fiber laser cutting machine can used in advertising sign production, sheet metal structure, high and low voltage electrical cabinet production, textile machinery parts, kitchenware, automobiles, machinery, elevators, electrical parts, spring sheets, subway parts, etc.

Brand: ZLTECH

Model: ZL3015BDC

Category: Fiber Laser Cutting Machine

Warranty: 3 Years

Payment: TT, Visa, Mastercard, Credit Cards, Paypal

Supply Ability: 200 Sets / Month

- Brand

- ZLTECH

- Model

- ZL3015BDC

- Country of origin

- China