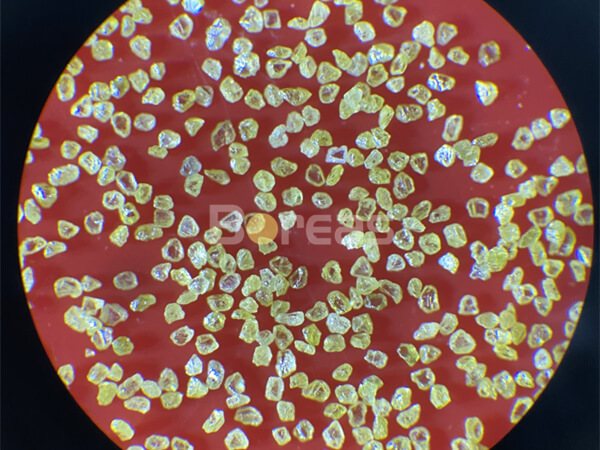

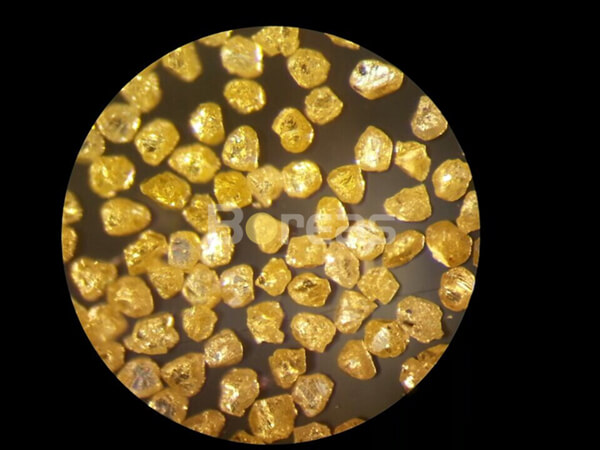

BRM-Z Reshaped Mesh Diamond Powder

Characteristics: Golden color monocrystalline particle, blocky shape, very higher purity, higher toughness, longer tool life and good finishing on surface.

Applications: Suitable for Metal, Vitrified and Electroplated bond system such as Grinding and Polishing the precision optical glass and other precision tools.

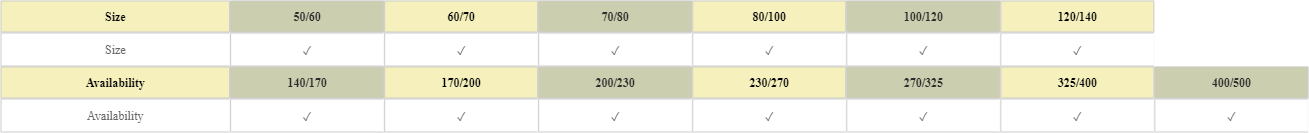

Available Size: 50/60 to 400/500

Synthetic diamond micron powder is a new type of super-hard and ultra-fine abrasive formed by artificial diamond single crystal through special processing. It is an ideal raw material for grinding and polishing high-hardness materials such as cemented carbide, ceramics, gems, and optical glass. Approximately 90% of diamonds used in various industries are manufactured synthetically.

Boreas are professionally manufacturing synthetic diamond powder since 1990. We have professional engineers and synthetic diamond experts serving world-class customers all around the world.

Our production line is equipped with advanced modern instruments, such as topography analysis system, plasma ICP detector, Laser particle size analyzer, Malvern 2000, SEM, etc.

Our control of the quality of diamond micron powder has completely entered the world of microscopic particles throughout the various stages of crushing, shaping, cleaning, classification, purification, identification, storage and transportation. Our coating technology on micro-powder is also in a leading position, with high surface roughness, uniformity and particle size distribution.

Boreas has been assessed as High-tech enterprise in 2015, certified by ISO9001, ISO14001, ISO45001.

Boreas annual production capacity: 600 Million CTS/Year.

Application:

• Making metal bond

• Vitrified bond

• Electroplated diamond tools for processing 3C industry

• Gem

• Glass

• Ceramic

• Tungsten carbide

- Model

- BRM-Z

- Country of origin

- China