Polyester Needle Filter Felt

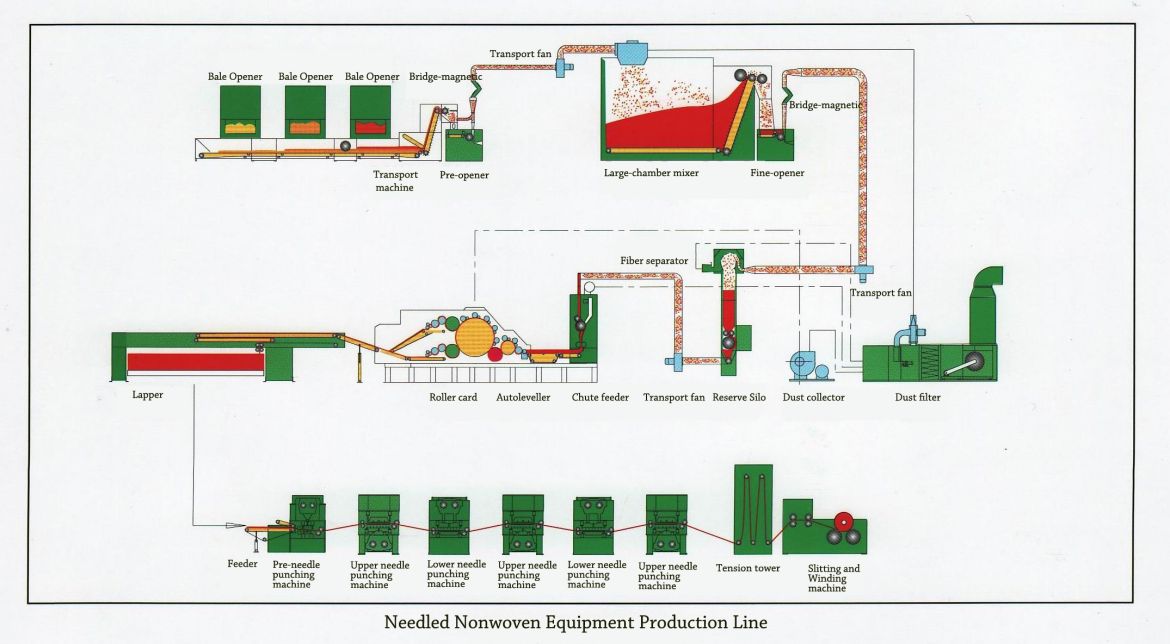

Polyester needle filter felt fabric is one kind of nonwoven felt made from Polyester fibers and Polyester scrim. It is a filter fabric widely used in industrial dust collector filtration under the working temperature of 130°C.

Daily output: 20000 sqm per day;

Thickness: 1.8-2.2mm;

Unit weight: 500-600gsm/sqm;

Width: 2.2m;

Components: 100% polyester fibers + polyester scrim;

Finishing: water&oil resistance, PTFE membrane, anti-static, fire resistance, double sides finishing would be available upon request.

Polyester needle punched felt advantages:

BY Polyester needle felt is made of different kinds of Polyester fibers(staple Polyester fibers and ultrafine filament Polyester fibers with different dentex) which makes our Polyester felt has better air permeability while with bigger breaking strength;

Polyester needle punched felt is made of staggered and uniformly distributed fine fibers to filter air, with a porosity of 70%, which is twice of Polyester woven filter cloth;

High dust collecting efficiency, low gas emission concentration;

The surface of the polyester needle punched felt is hot-rolled and singed or coated with PTFE to make it smooth, not easy to be blocked, not deformed, easy to clean dust, and has a long service life;

Polyester needle punchedfe felt is the most cheap filter material among all the filter materials.

Polyester needle filter felt advantages:

BY Polyester needle felt is made of different kinds of Polyester fibers(staple Polyester fibers and ultrafine filament Polyester fibers with different dentex) which makes our Polyester felt has better air permeability while with bigger breaking strength;

Polyester needle punched felt is made of staggered and uniformly distributed fine fibers to filter air, with a porosity of 70%, which is twice of Polyester woven filter cloth;

High dust collecting efficiency, low gas emission concentration;

The surface of the polyester needle punched felt is hot-rolled and singed or coated with PTFE to make it smooth, not easy to be blocked, not deformed, easy to clean dust, and has a long service life;

Polyester needle punchedfe felt is the most cheap filter material among all the filter materials.

Polyester needle filter cloth parameter:

Weight: 500-650 g/m2

Fiber Content: Polyester Scrim

Scrim fliament polyester

Continuous Operating Temperature: 130°C

Maximum Surge Temperature: 150°C

Acid Resistance: Fair

Alkali Resistance: Fair

Hydrolytic Resistance Poor

Oxidation Resistance Good

Abrasion resistance Excellent

Breaking Strength

Warp: 1300 N/5 cm

Fill: 1500 N/5 cm

Mullen Burst: 4654 kPa (675 psi)

Thickness: 1.8-2.0 mm

Working life time 8000 hours and more

Polyester needle filter felt application:

Polyester filter media is commonly used for industrial filtration is because it provides a reliable, durable material for filter bags and it can withstand higher solid loading than other materials.

Polyester filter felts applicable industry: Mining,Cement Industry,Iron and Steel Industry,Aluminum and Non Ferrous Industry,Ceramic Industry,Quarrying,Plastics,Milk Powder;

Packing & Delivery & How to order?

1. Packing can be customized, normally our Polyester felt is packed to rolls by woven bag, 75meters per roll.

2. ETD: 10 -15 days after receiving your deposit;

3. Payment terms: 30% deposit, balance before shipping;

4. MOQ: 5000 sqm for Polyester needle punched felts;

5. Transportation: We have good partners with the most economic way of logistics, including maritime, land, air and other ways, designated forwarder is also accepted. We can also assist your import procedures.

- Country of origin

- China