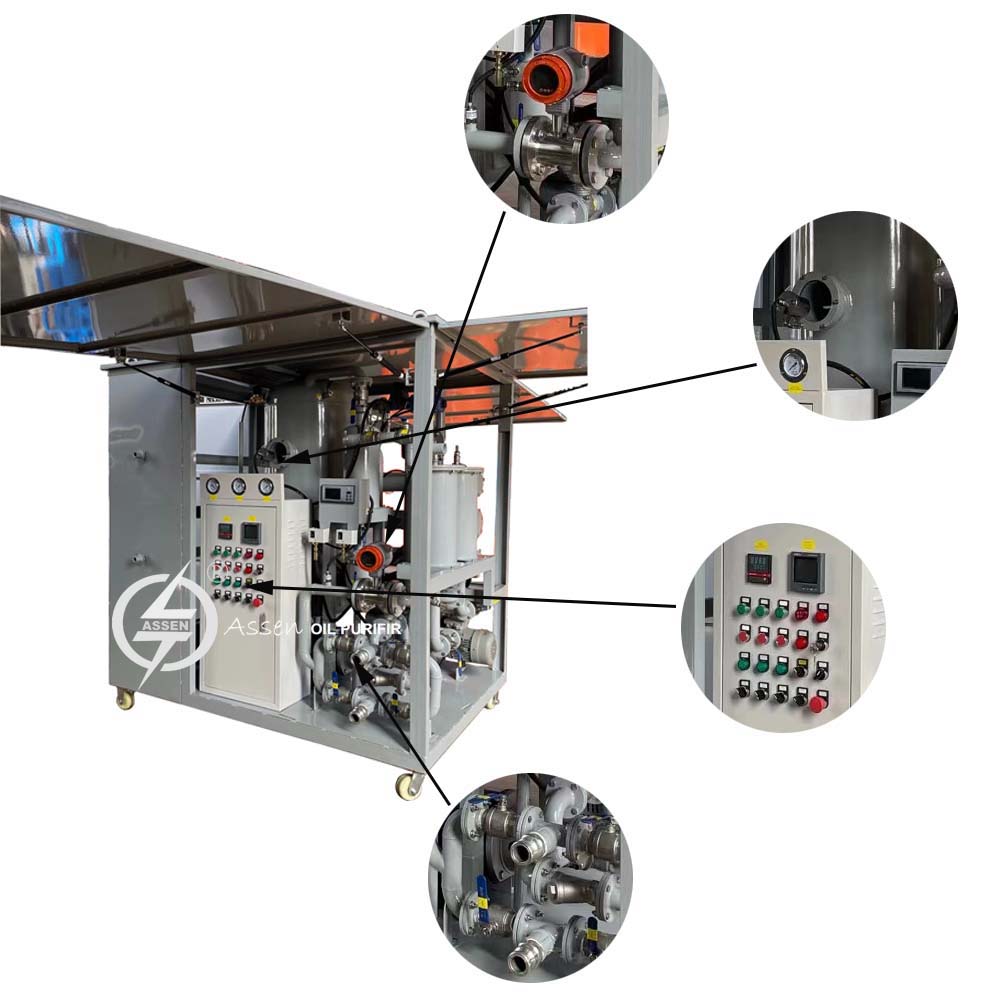

4000L/hr Full Enclosed type Transformer Oil Vacuum Dehydrator Plant

DVTP transformer oil vacuum dehydrator plant is widely used in the oil purification treatment vacuum hot oil circulation drying in the installation and maintenance of various large transformer equipment.

4000L/hr Enclosed type Transformer Oil Vacuum Dehydrator Plant

DVTP Oil Purification Plant will purify,dry and de-aerate oil to ensure dielectric strength and insulating properties of oil is restored.

Usage:

DVTP Double stage Transformer Oil Vacuum Dehydrator Machine is widely used in the oil purification treatment and vacuum hot oil circulation drying in the installation and maintenance of various large transformer equipment. Not only use in Insulating oil purification treatment in 110KV-550KV transformer but also applies to high-grade new oil, the high depth of processing imported oil.

The electrical properties of the oil can be enhanced by the filtering, dehydration, and degassing process of the ASSEN DVTP Transformer Oil Vacuum Dehydrator Plant, which also keeps the transformer in good condition and increases its life.

Technial Features:

A. Interchangeable Inlet & Outlet

A design that can switch oil inlet and oil outlet without changing the connecting hoses.

1.Used in the electric power system (110kV~500KV).

2.Features include low noise, high-strength working vacuum, and high efficiency filtering process.

3.Easy and failsafe operation.

4.On-line measuring and recording of process parameters.

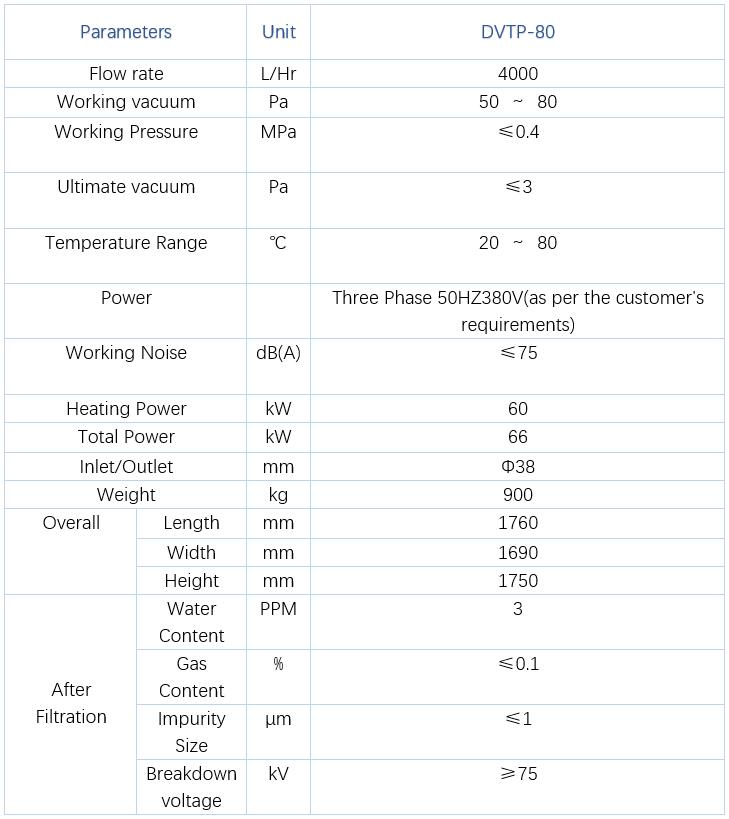

5.Double-stage vacuum system, strong power of vacuum evacuating, ultimate vacuum value ≤5Pa

6.The oil vacuum dehydrator unit can be used for the transformer vacuum oiling and for various wet electrical equipment vacuum drying.

7.Flexibility in application(flow frequency conversion, suitable for transformers of different sizes)

8.It is humanization design with low noise, deep purification and long time free maintenance to save cost from the running process.

B. Optional Online PPM Meter, Optional digital flow meter with accumulator function.

C. Advanced automatic thermostat control system, automatic liquid level control system, automatic defoaming control system, and automatic pressure protection system to ensure high-performance operation of the equipment.

D. All kinds of protection in the design, sensitive automatic pressure protection system and infrared liquid level control system, oil and heating interlocking safety protection system.

- Country of origin

- China