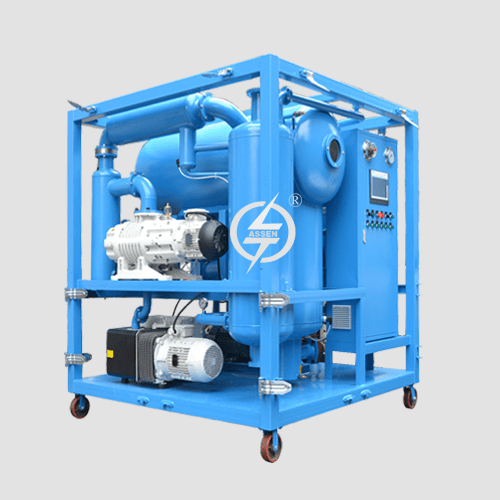

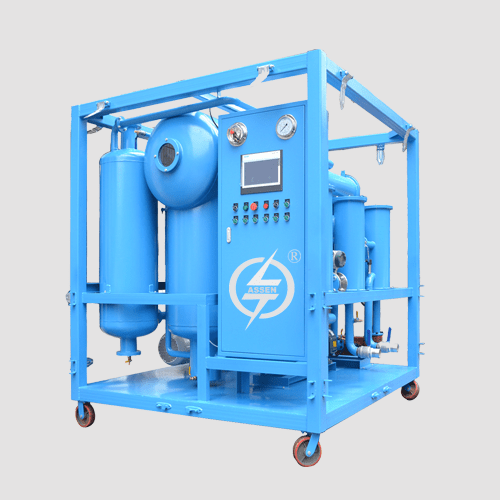

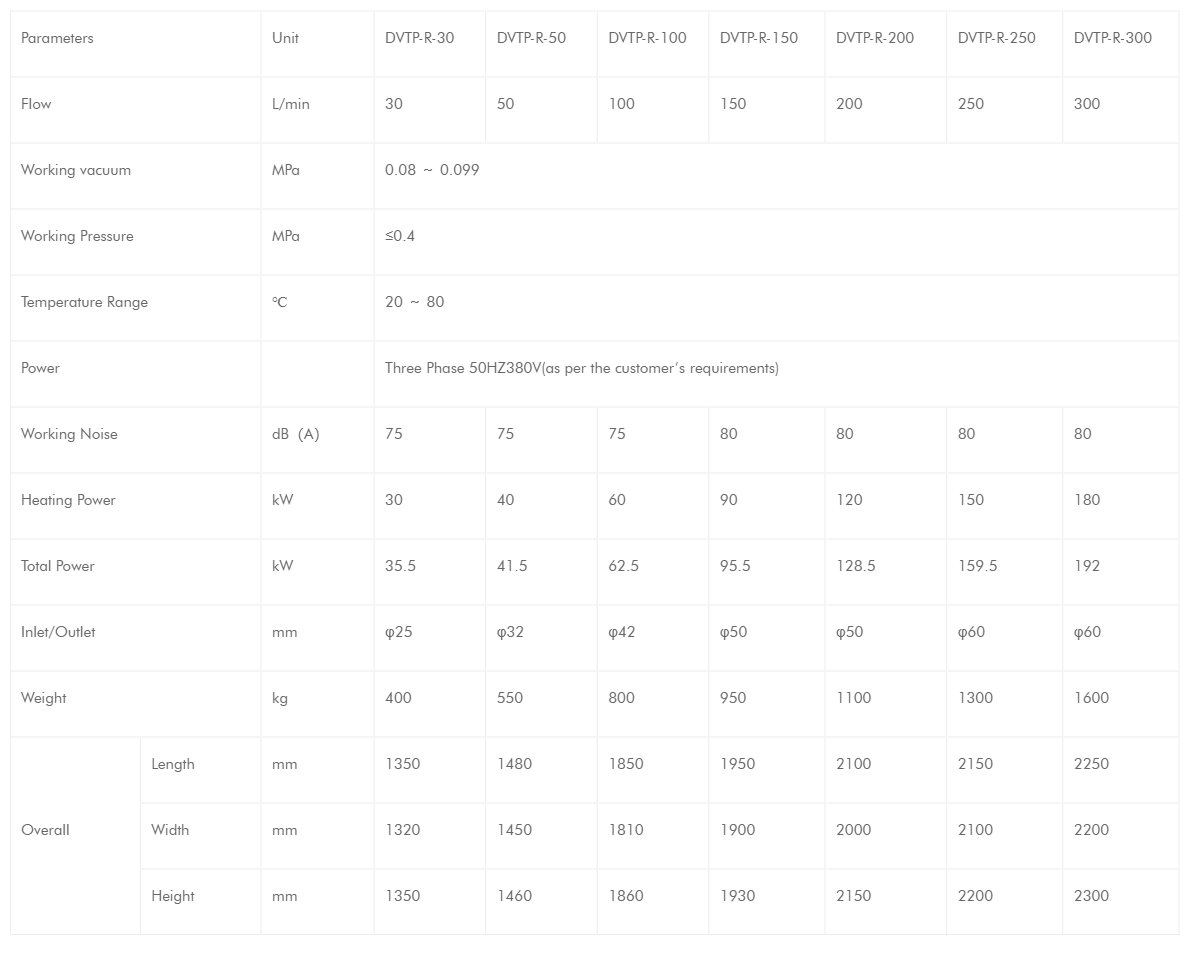

DVTP-R Series Double Stage Transformer Oil Regeneration Machine

DVTP-R Series Double-Stage Insulating Oil Regeneration machine has been specially designed for on site use to completely regenerate insulating oils in de-energized transformers.

Introduction:

ASSEN DVTP-R Insulating Oil Regeneration machine has been specially designed for on site use to completely regenerate insulating oils in de-energized transformers. Besides provides regular oil purification such as degassing, drying and particulate removal, it also can remove acidity, sludge, other soluble oil decay products and discoloration. After treating, the oil can be reused as new.

Fast remove moisture, gas ,particles, acidity, free carbon, and other soluble oil decay products in transformer oil, mutual inductor oil, cable oil, and circuit breaker oil, and restore property of insulating oil.

Performance:

In a single pass through the purifier at a full flow rate:

Water Removal: From 50 ppm down to less than 5 ppm in a single pass & down to 3 ppm after two passes. (According to the PPM Tester)

Gas Removal: From fully saturated with air (10% to 12% by volume) down to less than 0.1% by volume.

Particulate Matter Removal: 98% of particles over 0.5mm or over 1 mm or over 5mm at customers preference.

Dielectric Strength: Improve dielectric strength up to 75-80KV for New oil.

Acid Removal: after treatment, the acid value will down to less than 0.1mgKOH/g

Free Carbon Removal: there is no free carbon’s residue

Insulating Oil Regeneration's Technical Features:

1.Double-stage vacuum system, strong power of vacuum evacuating, ultimate vacuum value ≤ 5Pa

2.Two vacuum separating chambers, efficient oil film sprayer, increasing separating size and separating time to ensure the dry-level and dielectric strength improving greatly.

3.Double-horizontal film evaporation technology, combined with unique and advanced dewatering, degassing components, can rapidly and effectively separate water, gas from oil.

4.Multi-stage precision filtration system, mesh filtration combined with molecular adsorption technologies.

5.Efficient electric heating system, heating uniformity, less power consumption, safe, and reliable.

6.Double-infrared liquid level sensor, pressure protective system to ensure machine operation easy and safely.

7.Adopt interlocked protective system, which connect oil pump, heater and liquid level sensor, avoiding blank heating, blank pumping, oil leak and electricity leak. If there is any fault, machine will be power off automatically.

8.Functions of live line work onsite, vacuum drying and vacuum oiling.

- Country of origin

- China