Nickel Alloy Pipe & Tube

Standard: ASTM, ASME and API

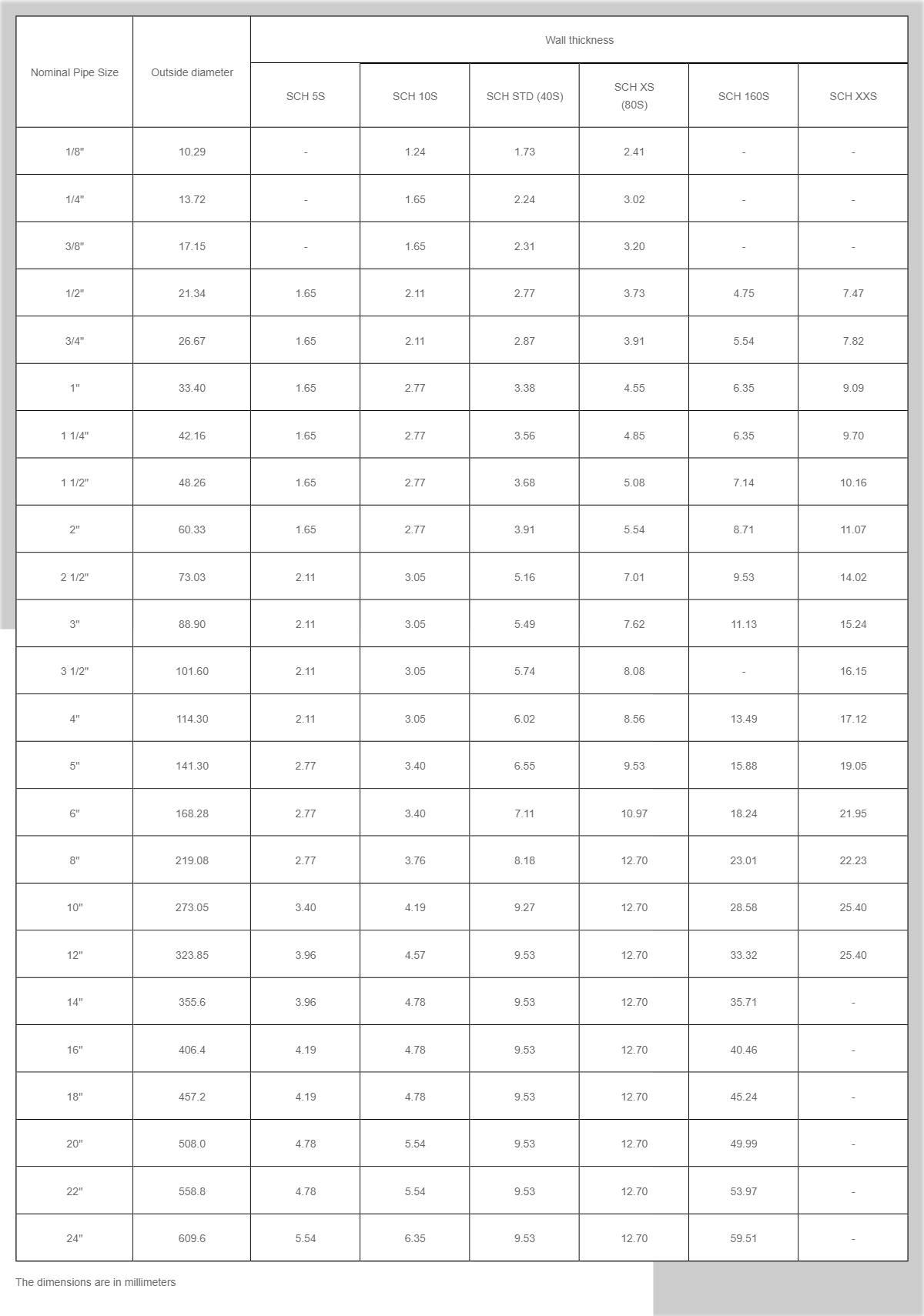

Sizes: 1 / 8" NB - 24" NB

Thickness: 0.3mm – 50 mm, SCH 5, SCH10, SCH 40, SCH 80, SCH 80S, SCH 160, SCH XXS, SCH XS

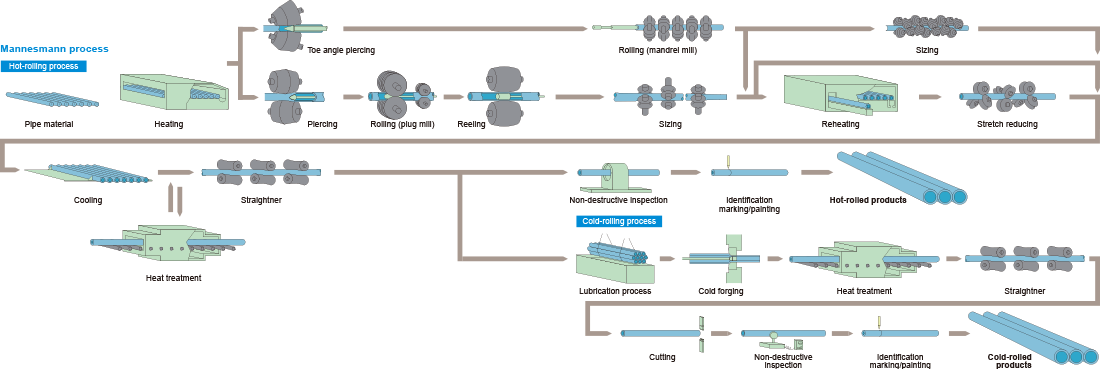

Type: Seamless / ERW / Welded / Fabricated / CDW

Length: Single Random, Double Random & Required Length

End: Plain End, Beveled End, T h readed

Nickel alloys are some of the most useful materials for manufacturing technically superior pipes and tubes for industrial applications. Their inherent properties make them viable for a wide range of uses. Nickel alloys are exceptionally corrosion resistant and can be used in high-temperature environments.

As nickel alloys are so ductile, they are very effectively machined to produce pipes and tubes, while retaining strength. This makes them good for use in heat exchangers in chemical processing, for example, which relies on tubing that can withstand both the hot and corrosive environment. Nickel-based tubes and pipes are also used in steam generators, aircraft systems, and in oil and gas extraction.

To meet the demand for these high-quality products, there are quite a few variants of nickel alloy pipes and tubes available on the market.

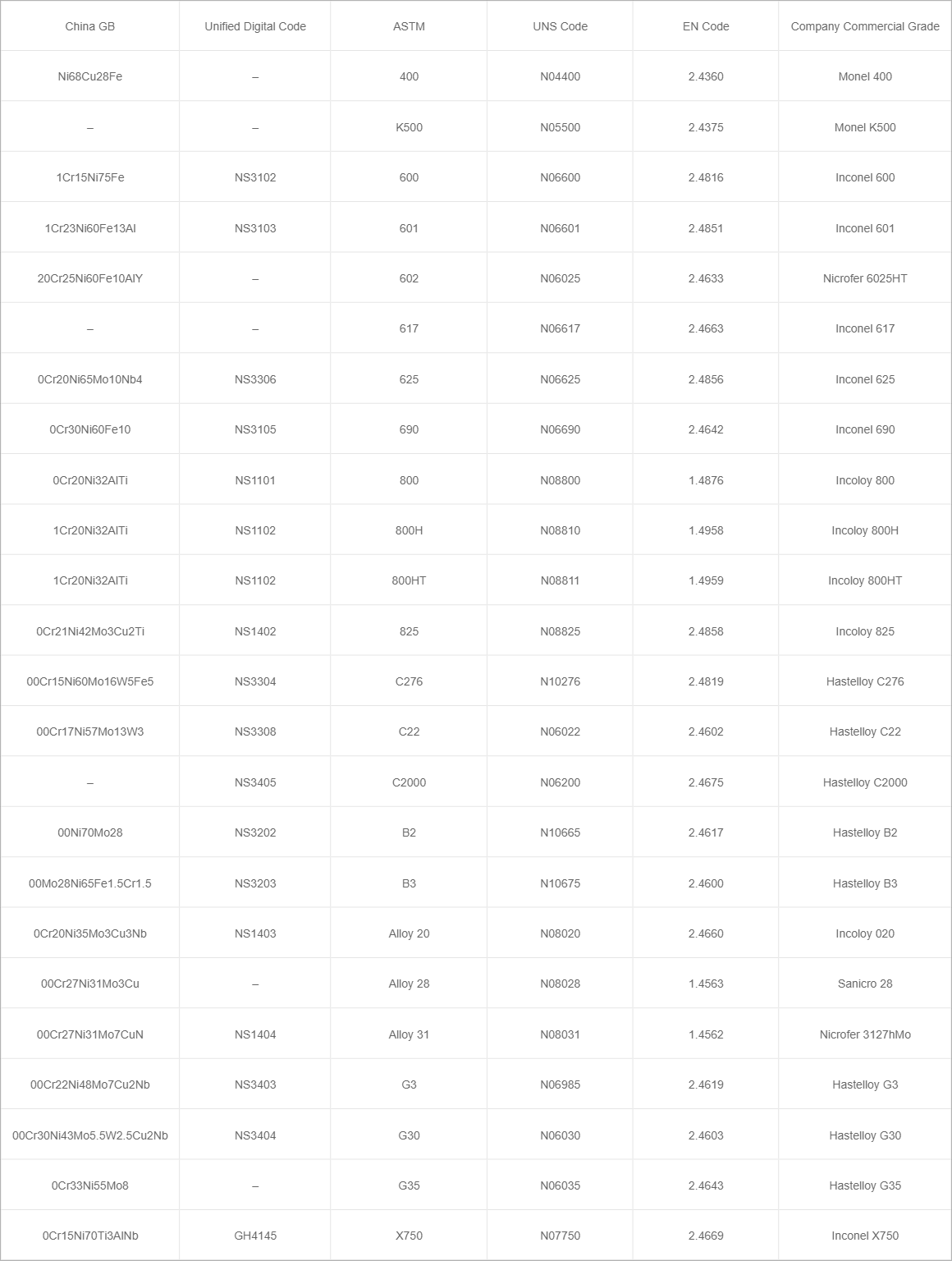

Common alloys for custom pipe & fittings include: Alloy 200, 201, 330, 400, 600, 601, 625, 718, 800, 800H, 800HP, 800HT, 825, 904L, AL6XN, Alloy 20, Alloy K500, C22, C276, Hastelloy X®, Inconel®, Monel®, Incoloy®.

- Country of origin

- China